Why Use Pogo Pin Connectors?

Below are the primary reasons for choosing Pogo Pin connectors:

1. High Reliability and Stability

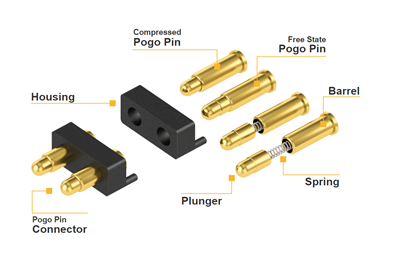

Spring-Loaded Contact: The built-in spring mechanism provides constant pressure, ensuring tight contact and minimizing connection issues caused by vibration or shock.

Wear Resistance: Gold- or nickel-plated pins resist oxidation and corrosion, making them ideal for frequent plugging/unplugging (e.g., charging ports, test fixtures).

Self-Alignment Capability: The spring's flexibility compensates for minor positional deviations, reducing alignment precision requirements.

2. Compact Design and Space Efficiency

Miniaturization: Small size suits space-constrained devices like TWS earphones, smartwatches, and micro-sensors.

Low Profile: Vertical design accommodates ultra-thin devices or complex internal layouts.

3. Water and Dust Resistance

Sealed Design: Some Pogo Pin connectors support IP67/IP68 ratings, using silicone seals or structural designs to block water and dust, ideal for outdoor or industrial environments.

4. Support for High-Frequency Signals and High-Speed Transmission

Low Impedance: Optimized electrical performance enables high-frequency signal transmission (e.g., USB 3.0, HDMI, 5G communication).

Low Contact Resistance: Stable electrical connections minimize signal loss and enhance efficiency.

5. Quick Connection and Automation Compatibility

Blind-Mating Design: Simplifies user operation by eliminating precise alignment (e.g., wireless charging docks, magnetic interfaces).

Automated Production: Compatible with SMT (Surface Mount Technology) processes, improving assembly efficiency and reducing labor costs.

6. Diverse Application Scenarios

Charging & Data Transfer: Wireless chargers, magnetic charging cables (e.g., Apple Watch chargers).

Testing Fixtures: Provides fast, stable connections for PCB testing and chip programming.

Wearable Devices: Hidden interfaces for smart bands, AR/VR devices.

Industrial Equipment: Quick-connect solutions for robotics and modular systems.

7. Long Lifespan and Low Maintenance

High Durability: Premium Pogo Pins endure tens of thousands of insertion cycles (e.g., over 100,000 cycles), outperforming standard connectors.

Easy Replacement: Modular design allows individual pin replacement, lowering maintenance costs.

Typical Applications

Consumer Electronics: TWS earphone charging cases, magnetic smartphone charging interfaces.

Medical Devices: Contact points for portable diagnostic tools.

Automotive Electronics: Test interfaces for in-car navigation modules and BMS (Battery Management Systems).

IoT Devices: Rapid docking for sensor modules.

Key Considerations

Contact Surface Cleanliness: Dust or oxidation may impair conductivity; regular cleaning is essential.

Current Limits: Select appropriately sized and material-graded Pogo Pins for high-current applications.

Cost Efficiency: While Pogo Pins have a higher unit cost than standard connectors, their long-term reliability reduces total ownership costs.

Summary

Pogo Pin connectors, with their spring-loaded contact mechanism, compactness, durability, and environmental adaptability, serve as efficient and reliable solutions in modern electronics. They excel in applications requiring frequent connections, miniaturization, or operation in harsh conditions.