Why Are More Engineers Choosing Pogo Pin Connectors for New Projects?

1. High Reliability and Durability

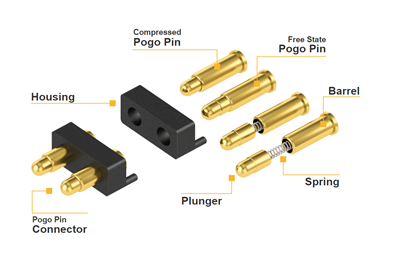

Wear-resistant design: The spring-loaded contact mechanism (via internal spring compression) minimizes physical wear, making them ideal for frequent plugging/unplugging scenarios (e.g., smartwatch charging, test equipment interfaces).

Self-cleaning capability: Sliding friction during contact removes surface oxidation, reducing the risk of poor connectivity.

Shock/Vibration Resistance: The spring buffer design ensures stable signal transmission in mobile devices (e.g., drones, automotive electronics).

2. Compact Size and Space Optimization

Miniaturization compatibility: Pogo Pins are ultra-compact (diameter <1mm), fitting into slim devices like TWS earbuds or medical tools (e.g., endoscopes).

Vertical stacking: Enables layouts in multi-layer PCBs or confined spaces, simplifying complex structures (e.g., foldable smartphone hinges).

3. Water and Dust Resistance

IP-rated protection: Achieves IP67/IP68 standards via gaskets or over molding processes, critical for outdoor gear (fitness trackers) or harsh environments (industrial sensors).

4. Design Flexibility and Customization

Adjustable parameters: Engineers can tailor tip shapes (pointed, flat), stroke length, and spring force to meet specific pressure/contact needs (e.g., high-precision test probes).

Multi-pin integration: Supports hybrid designs for power, high-speed signals, and data (e.g., VR headset unified power-data ports).

5. Enhanced Production Efficiency and Cost Savings

Automation-friendly: Connects without precise alignment, streamlining robotic assembly (e.g., smartphone battery production lines).

Lower maintenance costs: Long lifespan reduces replacements, vital for hard-to-service devices (e.g., implantable medical equipment).

6. Expanding Application-Driven Demand

Wearables: Devices like the Apple Watch use Pogo Pins for wireless charging/data transfer, balancing aesthetics and water resistance.

Modular systems: Cameras (e.g., Insta360) and industrial robots leverage Pogo Pins for quick module swaps.

Testing fixtures: Semiconductor probe cards ensure precise chip pad contact for high-frequency testing.

Medical devices: Endoscopes and portable monitors require reliable, sealed connectors.

Key Considerations and Limitations

Initial costs: Custom Pogo Pins may have higher upfront costs but offer long-term ROI.

Current limits: Miniaturized pins may not suit ultra-high-current applications; proper sizing is critical.

Conclusion

Pogo Pins have become engineers' go-to solution for compact, reliable, and durable connectivity in miniaturized, high-frequency, or harsh environments. As IoT, wearables, and Industry 4.0 evolve, their applications will continue to grow, driving innovation and product advancements.