What are the production techniques of Spring Pogo Pin?

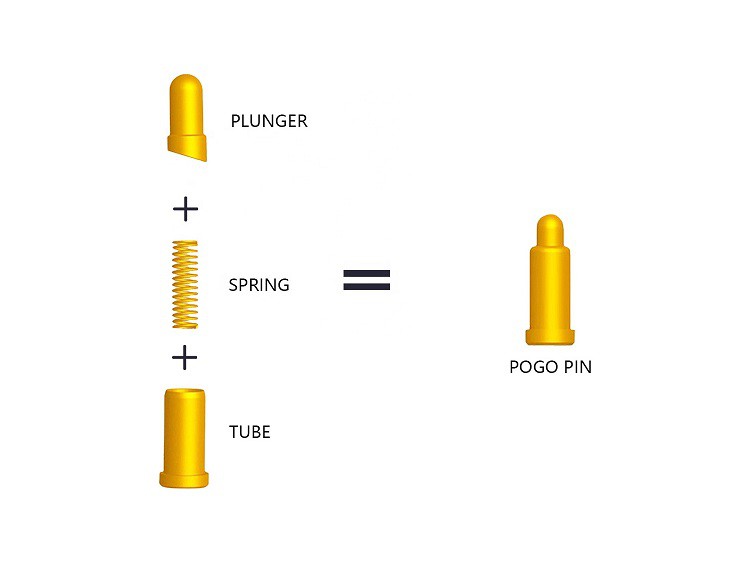

The pogo pin is the core component of precision connectors used in communication base stations or terminals, automobiles, unmanned aerial vehicles, industry, aerospace, and other fields. Both signals and current can be transmitted through the pogo pin. With the development of society, more and more products require high current transmission, fast charging, and even some products have requirements for lightning protection, so the current resistance of the spring thimble is getting higher and higher, so its production technology is Which ones? Let's take a look together next.

Several manufacturing techniques of existing spring thimble:

1. Flat-bottomed spring thimble: The needle of this structure is flat-bottomed, simple to process, lower cost, and the coaxiality of the needle tube is better, but there is a greater risk of the needle not contacting the needle tube and the risk of power failure, and the contact impedance of the product It is also very large. Products with this structure are generally only used on occasions where the product requirements are very low and the current is very small. Now regular large companies have not adopted this structured product.

2. Sectional bevel spring thimble: The needle of this structure is a sectioned bevel, the processing is complicated, the cost is high, and the coaxiality of the needle and the needle tube is poor, but the product needle and the needle tube are in good contact, and the contact impedance is also very small. The main reason is that the spring is the opposite. The needle elasticity has a lateral component force, which makes the needle and the needle tube stable in contact. This structure is widely used in spring thimble factories, and it is only used in small and medium current situations.

3. Steel ball spring thimble: The needle of this structure has a cut bevel, and a steel ball is added below it. The structure is complicated to process, the cost is high, the coaxiality of the needle and the needle tube is poor, and the needle tube takes up a lot of space, but the product needle and the needle tube are in good contact, and the contact impedance is also very small. The main reason is that the spring has a side to the needle elasticity. The component force in the direction of the needle makes the needle and the needle tube stable in contact. The steel ball also adds a current flow channel. This structure is widely used in spring thimble factories, and it is only used in situations where the current is medium and large.

4. Inner sleeve spring thimble: The needle of this structure is a cut bevel, and an inner sleeve is added under it. The structure is complicated to process, the cost is high, and the coaxiality of the needle tube is poor, and the space occupied by the needle tube is smaller than that of the steel ball type, but the product needle and the needle tube are in good contact with the needle tube, and the contact impedance is also very small. The main reason is the elastic force of the spring on the needle. There is a lateral force component, which makes the needle and the needle tube stable in contact. The inner sleeve also adds a current flow channel. This structure is widely used in spring thimble factories, and it is only used in situations where the current is medium and large.

The above content gives you a detailed introduction to the production technology of pogo pins, hoping to help you understand and understand this aspect.