The Method of making spring pogo pin contacts

Today, the spring thimble manufacturers are here to talk with everyone about the production method of the spring contact, a spring contact, which is built into the test socket used to test the integrated circuit (IC), so that the terminal of the IC (lead) It is electrically connected to the pad of a printed circuit board (PCB) or the PCB inside electronic products such as personal computers (PC) and mobile phones is electrically connected to IC terminals such as CPUs, etc., for electrical connection between contacts and terminals. So what is it like? Next, let's take a look.

This kind of spring contact has the function of electrically connecting the PCB and the terminal of the IC, which is the core component of the socket for testing the IC. Existing spring contacts are difficult to minimize the outer diameter of the spring. In order to make a spring contact with an outer diameter of 0.2mm, the wire diameter of the spring and the shape and size of the upper and lower contact pins will become very small. There are difficulties in processing and assembly at the current technical level. Therefore, in mass production and There are difficulties in quality, and there are limitations in the structure of contacts for extremely small pitches that are too expensive. Pogo pin is a kind of hardware that conducts current and transmits signals. Many friends also call it a signal pin. It can realize the power of the conduction function. Most of it is in contact with the copper wall through the pogo pin needle obliquely downward, and the pogo pin thimble spring bears a small amount Because of the high gravity, the inner wall of the copper sleeve is required to be smooth. Pogo pin has the characteristics of anti-corrosion, high stability, and high durability. So what is the composition of the pogo pin produced by the manufacturer?

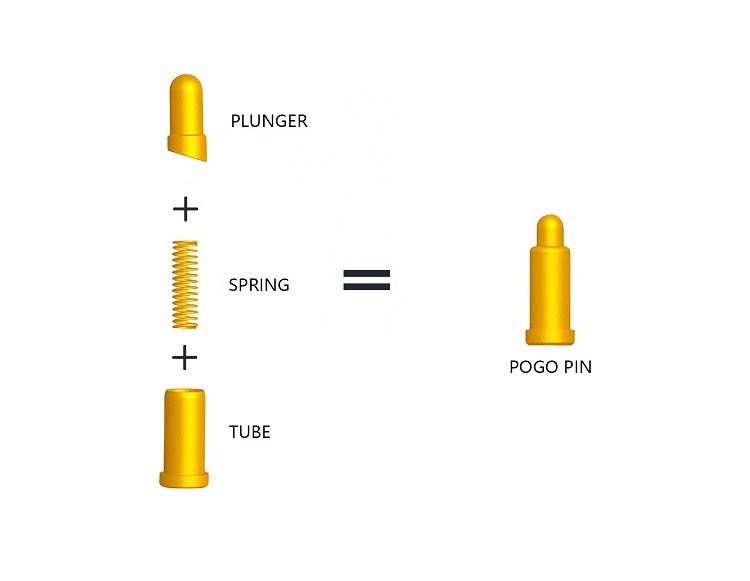

Pogo pin is a spring-type probe formed by arranging three parts of needle shaft, spring, and needle tube, using riveting precision instruments and riveting and preloading. Its internal structure is a precision spring structure. During the production process of pogo pin manufacturers, the surface will be plated with gold, which can better improve its anti-corrosion function, mechanical performance, electrical performance, etc. The needle tip has sharp needles, claw-shaped needles, round-end needles, knife-shaped needles, etc. Because of its special and precise structure, it is widely used in precision connectors, which can greatly reduce the weight and appearance of the connector, and make smart devices more exquisite and beautiful.

Pogo pins can now be used in many industries. With the widespread use of electronic devices, especially the popularization of mobile terminal devices, many products are inseparable from pogo pin. For example, the antenna used to receive the signal inside the mobile phone will use it as a mobile phone signal transmission device. Its advantages are strong anti-interference ability and low inductance. In addition to the pogo pin, which is used in mobile phones, it can be seen on many wearable devices, such as smartwatches, smart bracelets, smart shoes, locators, Bluetooth headsets, school bags, and other products. In addition to these, the pogo pin is also widely used in smart homes, medical equipment, industrial equipment, drones, smart robots, car navigation, military communications, aerospace, and other scientific and technological fields.

The above content gives you a detailed introduction to the production method of the spring contact. I hope the above content can help you understand this aspect.