TWS Headset Charging Pogo Pin

1) Total stroke: 1.10mm.

2) Working position: 4.5mm.

3) Spring Force:75±25gf at working height

4) Mechanical life: 30,000 cycle min.

TWS headset charging pogo pin

Materials and plating for Spring Pogo pins:

| Materials and plating for Spring Pogo pins | |||

| plunger | Material | BeCu | Most used material for spring probe for semiconductor. |

| Material | Pd Alloy | Effective for anti-solder migration. No plating is needed. | |

| Plating | Au Alloy | Hardness is higher than Au(Gold) plating and is effective for anti-solder migration. | |

| Plating | Au(Gold) | Good electric conductivity. | |

| Barrel | Material | Copper | Brass, Phosphor Bronze, Nickel Silver, BeCu |

| Material | Alloy | Barrel developed by ourselves. Outer diameter is available from 0.11 to 0.42mm | |

| Plating | Au(Gold) | Good electric conductivity. | |

| Spring | ― | Spring Steel Wire (SWP)(Music Wire) | Operating temperature: -45~125℃ |

| ― | Stainless Steel Wire (SUS) | Operating temperature: -45~140℃ | |

| ― | Stainless Steel Wire for high temperature | Operating temperature: -45~200℃, developed by ZZTKJ. | |

Manufacture machines & Testing Equipment

At present, our company has more than 80 automatic precision lathes, mainly Japanese STAR core moving machines, Taiwan Mingyang cutting machines, with mature and stable manufacturing technology.

Lathes machine

Cutting machines

Electroplating production testing equipment

We have an electroplating workshop. Adhering to the company's long-term development and the concept of excellence in quality, we start from the details, strictly control the process parameters of each production process, and provide the most suitable electroplating program according to the requirements of different customers and different products.

Electroplating workshop

Electroplating workshop

Assembly Line:

The skilled assembly process, under the guidance of SOP operating instructions, strictly abide by the assembly production process and operating specifications, to ensure that each link is controllable, and constantly optimize the quality of the product.

Skilled worker

skilled assembly

Quality Assurance System

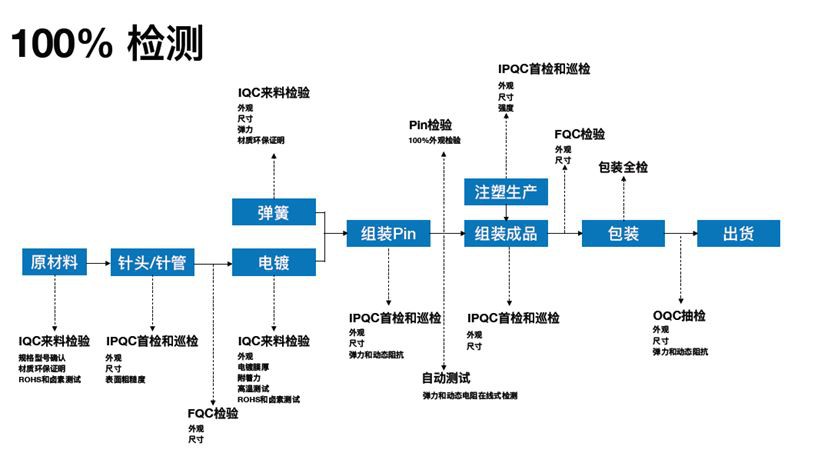

100% Inspection

The production documents and quality control documents are complete, and the product size and key parameters of the first article and inspection are operated, confirmed, and recorded in accordance with the requirements of SIP and SOP;

Hot Tags: tws headset charging pogo pin, China, suppliers, manufacturers, factory, customized, wholesale, buy, bulk, in stock, free sample

Send Inquiry