Welding Skills of Pogo Pin Female Connector

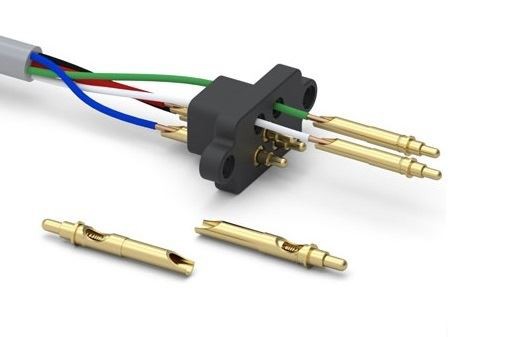

Because of the small size of the female connector, the four pins of the pogo pin connector interface are generally difficult to solder, and if the distance between the pins is too close during soldering, two of them may be inadvertently The pins are soldered together. Faced with this situation, you can use flux to wipe the solder joint pins before soldering. Be careful not to stick too much flux, because it is difficult to wipe off later, and the role of flux is not only to make the soldering smoother but also to fix the effect that the USB port is not easy to move when soldering.

After applying the flux, use a soldering iron to clean the tin on each solder joint. The purpose is to prevent excessive tin from causing false soldering. At this time, only a little tin is left on the surface of the solder joint.

Then put the pogo pin female connector on the pad, and gently put it in the alignment position. After placing it, press the pin with a soldering iron lightly. After a few seconds, it can be soldered.

When soldering the pogo pin female connector, pay attention to the operation force not to be too strong, to avoid causing the pins of the female socket to be easily bent by force, and the pads will show unevenness, resulting in the female There is false welding or false welding when welding the seat.

Note that after the final welding is completed, you need to use a multimeter to measure the diode to check whether the welding is good. For example, whether there is any looseness or false soldering of the pins, and if there is any phenomenon, the soldering should be repeated.