Pogo Pin Salt Spray Corrosion Principle

Do you know how long the salt spray test is equivalent to the natural environment for one hour?

Most of the corrosion of metal materials occurs in the atmospheric environment because the atmosphere contains corrosive components such as oxygen and pollutants, as well as corrosive factors such as humidity and temperature changes. Salt spray corrosion is a common and most destructive atmospheric corrosion.

Principle of salt spray corrosion

The corrosion of metal materials by salt spray is mainly due to the infiltration of conductive salt solution into the metal to undergo electrochemical reactions, forming a "low potential metal-electrolyte solution-high potential impurity" micro-battery system, electron transfer occurs, and the metal as the anode dissolves. Formation of new compounds known as corrosion products. Chloride ions play a significant role in the process of salt spray corrosion damage, which has a strong penetrating ability and can easily penetrate the metal oxide layer into the metal interior, destroying the passive state of the metal; at the same time, chloride ions have very small hydration energy, It is easy to be adsorbed on the metal surface, replace the oxygen in the oxide layer that protects the metal, and damage the metal.

Salt spray corrosion test method and classification

The salt spray test is an accelerated corrosion resistance evaluation method of an artificial atmosphere. It atomizes a certain concentration of salt water; then sprays it in a closed thermostatic box, and reflects the corrosion resistance of the tested sample by observing the changes of the tested model after it is placed in the box for a period of time. It is an accelerated test method, the salt concentration of chloride in the salt spray environment is several times or dozens of times that of the general natural environment salt spray content, which greatly increases the corrosion rate, and the salt spray test on the product shortens the time to obtain the result.

It may take a year or even several years to test a product sample in a natural environment, but similar results can be obtained in a few days or even hours in an artificially simulated salt spray environment.

There are four main types of salt spray tests:

① Neutral salt spray test (NSS)

② Acetic salt spray test (AASS)

③ Copper Accelerated Acetic Salt Spray Test (CASS)

④ Alternating salt spray test

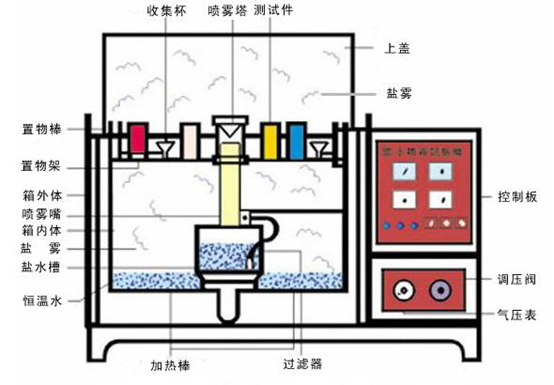

Salt spray corrosion test equipment

How long is one hour of salt spray test equivalent to the natural environment?

The salt spray test is divided into two categories: the natural environment exposure test and the artificially accelerated simulated salt spray environment test.

The artificial simulation salt spray environment test is to use test equipment with a certain volume space - the salt spray test chamber, and uses artificial methods in its volume space to create a salt spray environment to assess the quality of the product's salt spray corrosion resistance. . Compared with the natural environment, the salt concentration of chloride in the salt spray environment can be several times or dozens of times that of the general natural environment salt spray content, which greatly increases the corrosion rate. The salt spray test is carried out on the product and the results are obtained. The time is also greatly shortened. For example, if a product sample is tested in a natural exposure environment, it may take 1 year for it to corrode, but it only takes 24 hours to obtain similar results in an artificially simulated salt spray environment.

The artificial simulated salt spray test includes a neutral salt spray test, acetic acid salt spray test, copper salt accelerated acetic acid salt spray test, and alternating salt spray test.

(1) Neutral salt spray test (NSS test) is the earliest and most widely used accelerated corrosion test method. It uses a 5% sodium chloride saline solution, and the pH value of the solution is adjusted in the neutral range (6-7) as a solution for spraying. The test temperature is 35°C, and the sedimentation rate of salt mist is required to be between 1 and 2ml/80cm².h.

(2) The acetic acid salt spray test (ASS test) is developed on the basis of the neutral salt spray test. It is to add some glacial acetic acid to the 5% sodium chloride solution so that the pH value of the solution is reduced to about 3, the solution becomes acidic, and the final salt spray is also changed from neutral salt spray to acidic. Its corrosion rate is about 3 times faster than that of the NSS test.

(3) Copper salt accelerated acetic acid salt spray test (CASS test) is a rapid salt spray corrosion test recently developed abroad. The test temperature is 50°C. corrosion. Its corrosion rate is about 8 times that of the NSS test.

Under general environmental conditions, you can roughly refer to the following time conversion formula:

Neutral salt spray test 24h ⇌ natural environment 1 year

Acetate salt spray test 24h ⇌ natural environment for 3 years

Copper salt accelerated acetate salt spray test 24h ⇌ natural environment for 8 years