Spring-loaded PogoTest Pins

Spring-loaded Pogo Test Pins: The Ultimate Solution for Reliable and Efficient Testing

Testing electronic circuits and printed circuit boards (PCBs) is an essential part of the manufacturing process. To ensure the functionality and reliability of the end product, it is necessary to perform various tests such as continuity, functional, and parametric tests. However, testing can be a challenging and time-consuming task if the right tools are not used. This is where spring-loaded pogo test pins come into play.

What are Spring-loaded Pogo Test Pins?

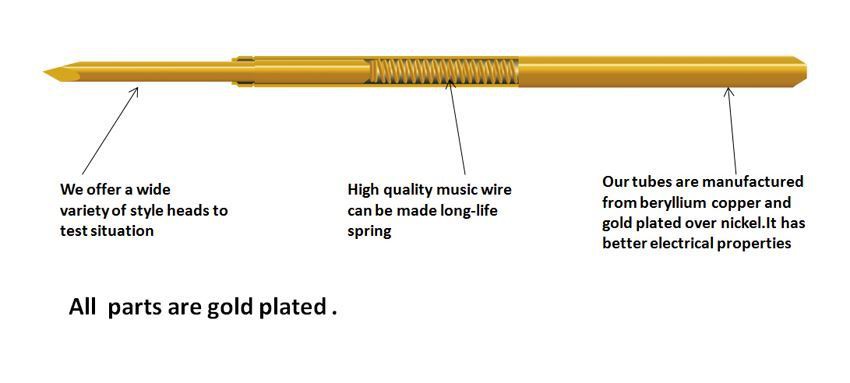

Spring-loaded pogo test pins are specialized test probes designed for use in testing electronic circuits and PCBs. These pins are made up of a plunger, a spring, and a barrel. The plunger is a cylindrical-shaped rod that moves up and down while the spring provides the necessary force to retract the plunger after contact. The barrel is used to attach the pin to a testing machine.

Why Use Spring-loaded Pogo Test Pins?

Spring-loaded pogo test pins offer several advantages over traditional test probes. Some of the key benefits are:

1. Accurate and reliable measurements: Spring-loaded pogo test pins provide accurate and reliable measurements because the spring ensures that the plunger makes good contact with the test point.

2. Easy to use: Spring-loaded pogo test pins are easy to use because they require minimal force to make contact with the test point. This means that they can be used in automated testing environments.

3. Versatile: Spring-loaded pogo test pins are versatile because they come in a variety of sizes and shapes to fit different testing requirements.

4. Durable: Spring-loaded pogo test pins are durable because they are made of high-quality materials that can withstand repeated use and abuse.

5. Time-saving: Spring-loaded pogo test pins are time-saving because they reduce the testing time by providing fast and accurate measurements.

Applications of Spring-loaded Pogo Test Pins

Spring-loaded pogo test pins are widely used in the electronics industry for testing PCBs, semiconductors, and other electronic components. Some of the common applications of these pins are:

1. Continuity Testing: Spring-loaded pogo test pins are used in continuity testing to check the electrical connection between two points.

2. Functional Testing: Spring-loaded Pogo test pins are used in functional testing to check the performance of the electronic circuit or PCB.

3. Parametric Testing: Spring-loaded pogo test pins are used in parametric testing to measure the characteristics of electronic circuits such as resistance, capacitance, and inductance.

A lot of the stuff that we’ve been involved with is definitely at the advanced nodes. The massive parallelism of these devices is driving people to use the most advanced silicon nodes, especially for the logic part of it. We’ve seen some projects that are mind-boggling in terms of die size and transistor count. For a probe card manufacturer, that drives a very large number of probes. To get all of the power in, there are some thermal control issues associated with the test. But that whole test interface for logic chips is now approaching the numbers and scale that we saw in memory only a few years ago. State-of-the-art memory probe cards a few years ago had maybe 50,000 or 60,000 probes per card. We’re shipping probe cards with that number of probes to test some of these AI engines, as well. The scale of these things is astounding.

Our technology provides a way to fabricate probes with micron-level accuracy for connecting to I/O and power on us. The precision characteristics of probes make them ideal for the fine pitch, high pin count requirements of leading-edge semiconductor process nodes, and advanced packaging, but not all probes are created equal. Leveraging clad metal technology to enable a range of new IC frontier electronics innovations.

Spring-loaded PogoTest Pins

These are some very, very large die. When you think about the density and the sheer power you need to get into the chip, and then the number of interfaces it has to the outside world — these are very complicated interfaces, and therefore very complicated tests and test tooling. FormFactor made some really big investments in MEMS probe technology, which is the only cost-effective way to get to the kind of densities and performance levels that people need to test these kinds of chips. There are technical challenges, but it’s a really interesting field to be in because you’re working with some of the leading customers in the world to push this forward.

Spring-loaded PogoTest Pins

For the test part of the business, with any given engagement you got a very interesting customer set. It’s usually multiple entities at different geographic locations that you are working with at the same time. There is the fabless design house, the foundry, and depending on where the test is being done, there can be a testing house, too. And a lot of the test program development does go into some of the spaces of algorithm development and then how the end system is going to be deployed. There are a lot of engagements where you don’t have one customer. You have three customers for a single design. And everybody has to work together and communicate well for these things to work.

Spring-loaded PogoTest Pins

A lot of those challenges are the same themes we’ve seen as we’ve gone from 20nm down to the first nodes, and then to 10 and 7nm. One of the biggest test challenges customers have is the combination of power density and thermal control — trying to make sure that as they test the chip, the transistors, and the overall chip are operating at temperatures that are consistent with regular use cases. You can run a set of test vectors through a chip and produce an immense amount of heat, which then causes some weird physical interactions with the overall test. And so both thermal control, as it relates to throughput and test strategies, and then the amount of current you’re able to get in and out of the chip, are some of the biggest challenges we see at those advanced logic nodes. There is tremendous power density.

FAQ:

Q1: How we do:

1. 6 inline QIC and 12 final QC, Control Every step as your order

2. 136 skilled workers,15 experienced production workshop managers

3.12 professional sales managers, 7*24 hours service

Q2: Our Values: Win-win Business

Provide cheaper prices, better quality, fast delivery, and attractive products to the Client

Share More Money, Comfortable Environment, Education& Training with our workers

Q3: What We Guarantee:

Samples not good—refund

Production not good—refund or reproduce

Service not good—discount on orders

Q4: What you get:

Cheaper, cheaper, cheaper price, better, better, better Quality

Same price, our quality is better, same quality, our price cheaper

Steady quality as you order, production always comes same with samples

Fast Delivery, Own factory, can be adjustable if urgent

Quick response, comfortable communication, constrictive suggestions

Free samples, Smallest MOQ

Q5: Goal & Philosophy

To be your best Pogo pin & connecter, suppliers

The customer first, Employees second, and Shareholders third

Hot Tags: spring-loaded pogotest pins, China, suppliers, manufacturers, factory, customized, wholesale, buy, bulk, in stock, free sample

Send Inquiry