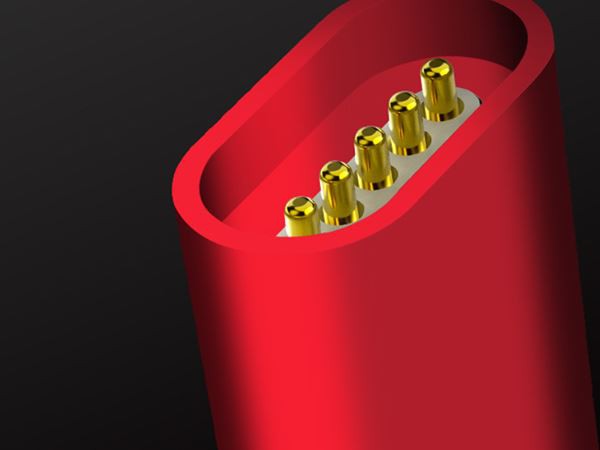

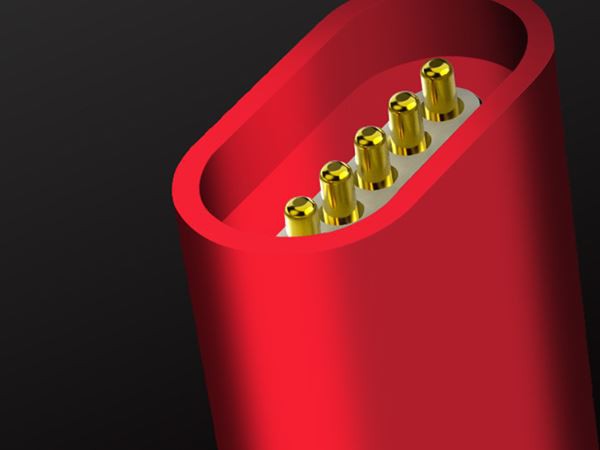

Spring-loaded Adapter Pogo Pin Connector

As with the power requirements, the Spring-loaded Pogo Pin Adapter must meet strict safety requirements due to direct contact with large voltages, especially in compliance with the international IEC1010 voltage and category requirements, namely CATI, CAT II, CAT III or CATIV. Other requirements of IEC1010 also involve transient testing, dielectric withstand voltage, or testing to verify that the product has sufficient insulation and meets the requirements for current, electrical clearance, exposed metal pogo pin spring pins, and impact resistance. Good quality test needles, together with important personal protective equipment such as gloves and eye protection, form part of the personal protective measures defined in the NFPA70E standard.

High-quality test leads and connectors will not suffer performance degradation due to daily friction such as pulling, pressing, and puncturing. Both ends of the test line should have well-designed anti-stress sheaths. The Spring-loaded Pogo Pin Adapter should be a hardened metal that can withstand repeated connections and can transmit accurate data every time.

Compared with cheap materials, specially manufactured strands of tinned beryllium copper wire can provide flexibility, long-term durability, excellent conductivity, and precision. Other factors include pogo pin spring pins and internal welding quality of the connector and the temperature range of the material.

It is very important to test whether the pogo pins are comfortable or not. A comfortable, easy-to-grab grip surface helps to hold the needle firmly in your hand, and a strong spring clamp ensures a firm connection. The connection should be simple, and matching parts should be able to slide together effortlessly without stress. The contacts on high-quality connectors should be nickel-plated or gold-plated machined brass connectors, not just cast brass. The use of gold-plated contacts provides accuracy and oxidation resistance, thereby providing a durable, safe and reliable connection.

The design index of the test line and pogo pin spring needle should be consistent with the matching test instrument. If the index is smaller than the test instrument, the true value of the instrument will be greatly reduced. For example, if the bandwidth of the oscilloscope is 100M, and the bandwidth of the matching oscilloscope needle is only 50M, then the oscilloscope becomes 50M.

✧ Manufacturing and Assembly Department

Have an independent machining and turning workshop to control every production process of the product from the source. Independent research and development of bevel pogo pin cutting technology, high processing precision, and stable products. Our company has a separate spring processing workshop, which is clean and dust-free, and controls every production process of the product from the source. The independent processing has high precision, strict control, stable performance, and quality assurance.

|  |  |  |

We strictly control every production process with advanced manufacturing equipment, starting from the production details. Our Assembly workshop: skilled assembly process, under the guidance of SOP operating instructions, strictly abide by the assembly production process and operating specifications to ensure that each link is controllable.

|  |  |  |

Hot Tags: Spring-loaded Adapter Pogo Pin Connector, China, suppliers, manufacturers, factory, customized, wholesale, buy, bulk, in stock, free sample

Send Inquiry