SMT Reflow Soldering Pogo Pin

SMT Reflow Soldering Pogo Pin: A Game Changer in Electronics Manufacturing

In the world of electronics manufacturing, getting consistent results with surface mount technology (SMT) reflow soldering can be a challenge. This process involves applying solder paste to the pads on a printed circuit board (PCB), placing SMT components onto the paste, and then heating the board to melt the solder and form the connections. However, variations in the size, shape, and weight of components can cause them to tilt or shift during the heating process, resulting in poor solder joints or even board failures.

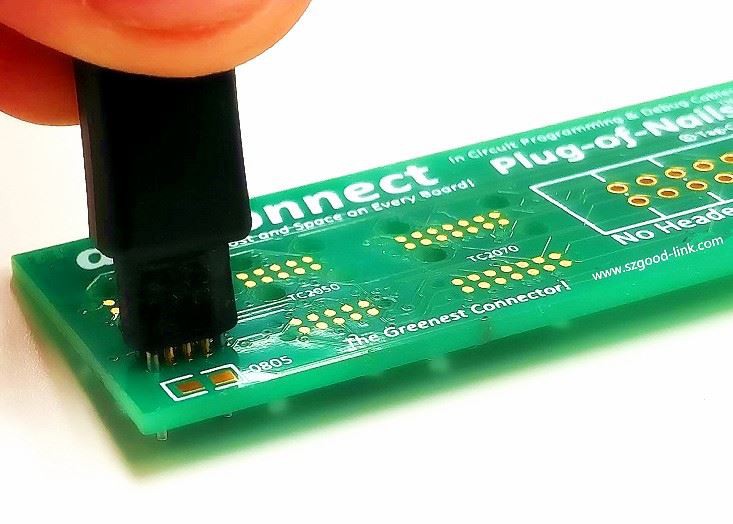

Enter the SMT reflow soldering pogo pin. This innovative tool acts as a spring-loaded guide that holds the SMT components in place during reflow, ensuring accurate and repeatable positioning. Pogo pins are small metal pins with a spring mechanism that allows them to move up and down when pressure is applied. They are commonly used in test fixtures and programming adapters to make electrical connections between PCBs and test equipment.

To use pogo pins for SMT reflow soldering, they are attached to a special fixture that aligns them with the pads on the PCB. The fixture is designed to hold the PCB and components upright during the reflow process, preventing them from tilting or sliding out of position. The pogo pins apply gentle pressure to the components, keeping them in contact with the solder paste as it melts and solidifies.

One of the key advantages of using pogo pins for SMT reflow soldering is that they allow for more precise control over the soldering process. By keeping the components in the correct position, the pins ensure that the solder joints are formed exactly where they are supposed to be. This reduces the risk of shorts, opens, or weak joints that can affect the performance and reliability of the finished product.

Another benefit of pogo pins is that they are quick and easy to set up and use. The pins can be easily mounted onto a fixture or adapter, and they do not require any special programming or calibration. This makes them a cost-effective solution for high-volume production runs, where speed and simplicity are essential.

Overall, SMT reflow soldering pogo pins are a game changer in electronics manufacturing. They provide a simple and effective way to improve the quality and consistency of soldering results, while also increasing productivity and reducing manufacturing costs. Whether you are a small-scale hobbyist or a large-scale production facility, pogo pins are a valuable tool to have in your electronics assembly toolkit.

There is already solder before the PCB is put on the furnace. After soldering, the applied solder paste is only melted for soldering. When wave soldering, there is no solder before the PCB is put on the furnace. The solder wave generated by the soldering machine coats the solder on the pads that need to be soldered. Finish welding.

SMT Reflow soldering pogo pin can be soldered on the PCB to fix it, and it can also be fixed in the product structure. These require professional design engineers to solve these problems.

Hot Tags: smt reflow soldering pogo pin, China, suppliers, manufacturers, factory, customized, wholesale, buy, bulk, in stock, free sample

Send Inquiry