What is the difference between different spring pogo pin structures?

The spring thimble is a precision instrument composed of three parts: a needle tube, a spring, and a needle shaft. The requirements in the processing process are also appropriate and strict.

First, flat-head spring thimble needle shaft:

1, spring thimble needle shaft flat head features: easy manufacturing process, low cost;

2. Processing and manufacturing process: turning process → vibration grinding process (removal of burrs, acute angles) → electroplating process;

3. The trembling grinding process is to remove the burrs and sharp angles that occur during processing and to reduce the shakshuka phenomenon during tightening.

Second, the hypotenuse type spring thimble needle shaft:

1. The characteristics of the hypotenuse of the needle shaft of the spring thimble: now commonly used in the factory, with good electrical characteristics;

2, processing and manufacturing process: turning processing → secondary processing of bevel edge → vibration grinding process (removal of burrs, acute angles) → electroplating process;

3. The tremor grinding process is to remove the burrs and sharp angles that occur during processing, and to reduce the shakshuka phenomenon when tightening;

4. There are two types of bevel angles in the factory now: 1) 12° → It is easy to assemble the pre-arrangement of the needle shaft, and the length of the needle seat is short, which saves space. 2) 18° → Now commonly used in the factory, the length of the needle holder is long, and the tightness with the pipe wall after assembly is high and the resistance value is good.

Third, reverse drilling type spring thimble needle shaft:

1, spring thimble needle shaft reverse drilling feature: suitable for products with large contraction stroke;

2. Processing and manufacturing process: turning processing → secondary processing reverse drilling → chattering grinding process (removing burrs and acute angles) → electroplating process;

3. The tremor grinding process is to remove the burrs and sharp angles that occur during processing, and to reduce the shakshuka phenomenon when tightening;

4. Now there are two kinds of angles of reverse drilling in the factory: 1)120°→easy to drill. 2)160°→It is not easy to drill, but it can add space for spring placement.

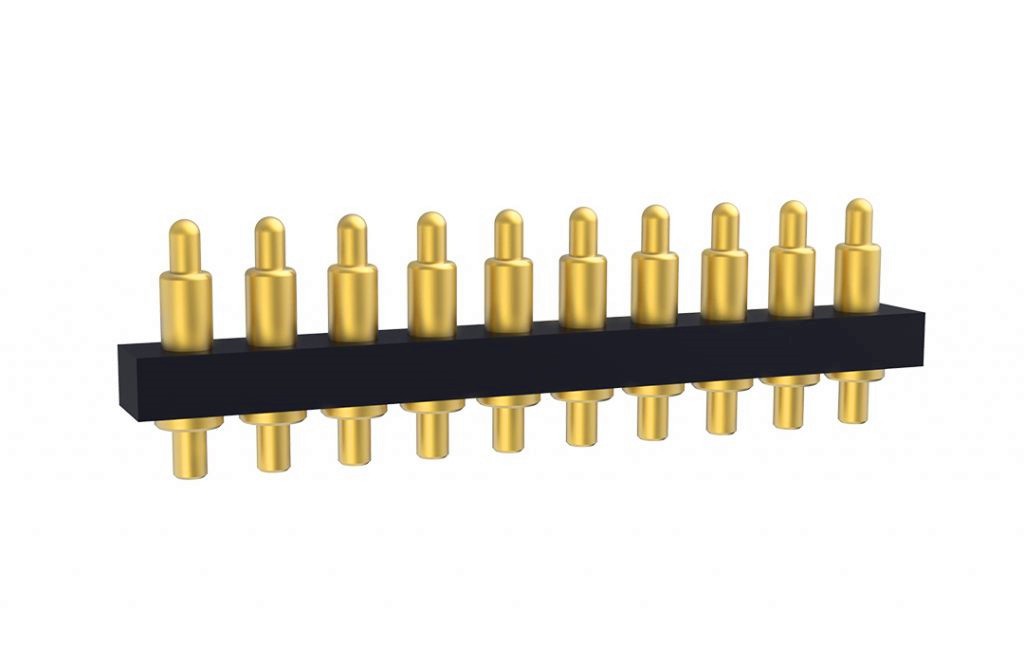

spring thimble connector belongs to a kind of connector, its function is very simple is to play the role of a connection. Spring thimble connectors can be drafted according to practical operating requirements, and different specifications can be selected in the drafting.