What factors affect pogopin spring Pogo Pin?

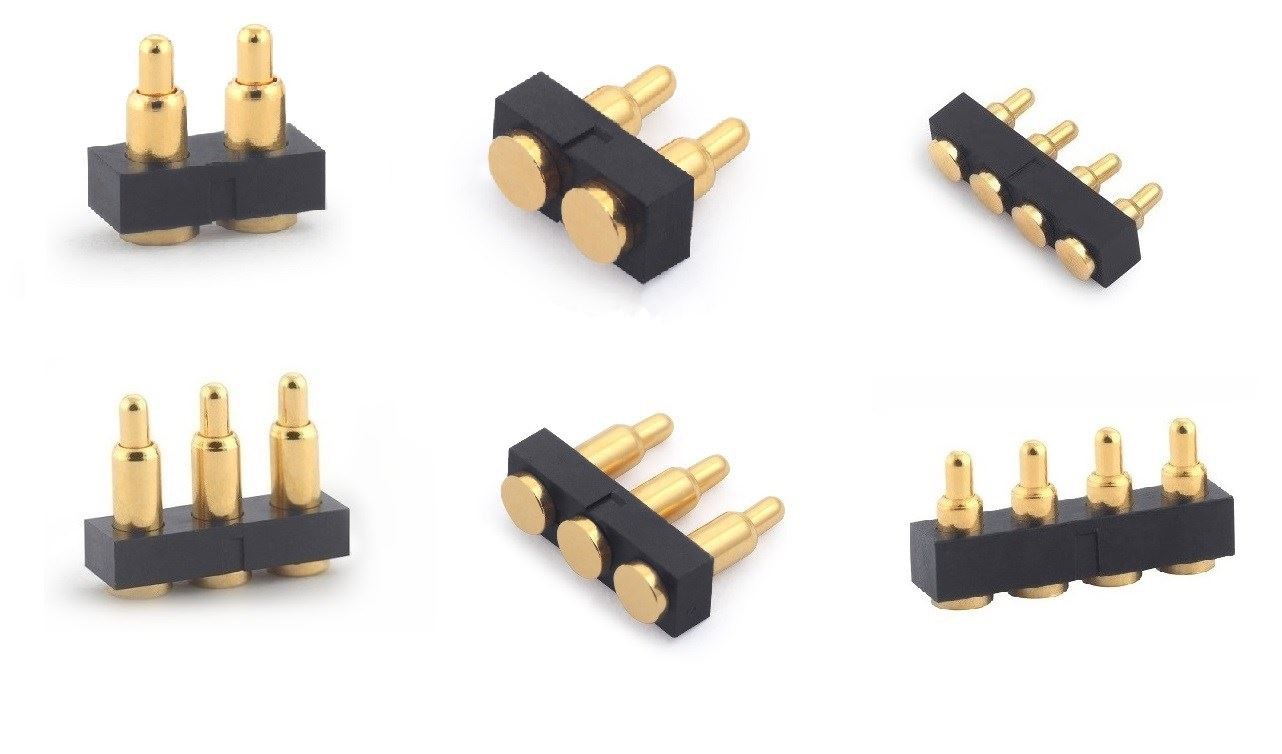

Current electronic and electrical products are developing in the direction of refinement, ease of installation, and long service life. The pogopin spring thimble connector is small in size and has a retractable design, which can well meet the needs of current electronic and electrical products, so pogopin spring thimble Connectors are loved by many connector manufacturers.

pogopin spring thimble is a very simple part, but the process requirements are very high, if there is no good quality control and perfect manufacturing process level, it is particularly prone to power failure and pin stuck, or too short life. The pogopin spring thimble technology is particularly delicate and complicated. From lathe processing, electroplating, and assembly, every link may bring serious hidden dangers.

Lathe processing:

Should be processed with Japanese automatic lathes, so that the precision of parts can be ensured within +/-0.01mm. Most factories use cutting machines for processing, and accuracy cannot be guaranteed. Secondly, the surface finish processed by the lathe, especially the inner surface finish of the pogopin spring thimble needle tube is very critical. Most factories do not have surface roughness testing equipment, that is, there is no parameter to supervise this.

Plating process:

The thickness of the plating layer has a great influence on the cost structure. The gold plating of the high-quality pogopin spring thimble is 16u", but most of the products are in 1~2u", which has a big gap. Secondly, the quality of the gold plating in the hole has a great influence on the electrical properties (impedance) and mechanical properties of the pin.

Assembly process:

The poor assembly process can cause serious problems such as skew of the needle, a large gap between the height of the needle, the pin stuck, and peeling of the nozzle.

It has an independent plant with an area of approximately 6,800 square meters. Integrating R&D, manufacturing, and sales, it is mainly engaged in the research and development and production of various POGOPIN and POGOPIN connectors, shrapnel terminals, and CNC automatic lathe parts. It can also be produced and processed according to customer samples. There are more than 4,000 product categories. For customers to choose, products (probe connector, pogo pin, pogopin, spring connector, magnetic pogopin, probe, charging pogo pin, magnetic pogo pin) are widely used in UAV smart robot smart wearable products 5G Communication products, smart home products, education/entertainment electronic products, medical equipment products, automotive electronics, mobile phone consumer electronics and other electronic products.