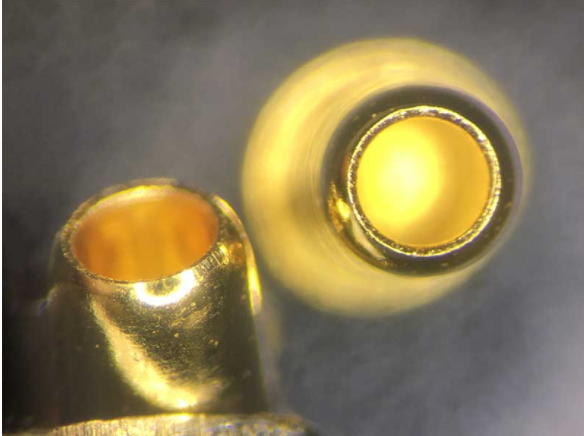

The reason why the surface of the pogo pin is gold-plated

As we all know, the needle and needle tube of the pogo pin connector are generally turned from brass, and copper is a very active metal. Copper will react with oxygen in the air when exposed to air. , thereby oxidizing. The main function of the pogo pin connector is to conduct current or electrical signals. Therefore, in order to ensure the electrical conductivity of the pogo pin connector, the pogo pin connector must be electroplated on the surface. The most common is gold plating on the surface, and some will require nickel plating, zinc plating, silver plating, rhodium ruthenium, and so on.

The gold plating process accounts for a very high proportion of the electroplating of pogo pin connectors. At present, except for some strip pogo pins that use a selective gold plating process, the gold plating in the holes of a large number of pinhole parts still adopts barrel plating and Vibration plating is performed. With the development of miniaturization of electronic products, in order to adapt to the development of the industry, the volume of connectors is also getting smaller and smaller, and the quality problem of the gold plating in the holes of the pinhole parts is becoming more and more prominent, and the quality requirements of users on the gold layer are becoming more and more. High, some users are even very picky about the appearance quality of the gold layer. In order to ensure the quality and bonding force of the gold-plated layer of the connector, these common quality problems are always the key to improving the quality of the connector's gold-plated layer. The reasons are discussed with you.

1. The color of the gold-plated layer of the pogo pin is abnormal

The color of the gold-plated layer of the pogo pin is inconsistent with the normal color of the gold layer, or the color of the gold layer of different parts in the same accessory product is different. This is one of the most common electroplating problems.

2. The influence of impurities in the gold-plated raw material of the pogo pin

When the impurities brought in by the chemical materials added to the plating solution exceed the tolerance level of the gold plating solution, the color and brightness of the gold layer will soon be affected. If it is affected by organic impurities, the gold layer will appear dark and flowery. The position of film inspection darkening and blooming is not fixed. If the metal impurities interfere, the effective range of the current density will be narrowed. The Hall cell test shows that the current density of the test piece is not bright at the low end or the high end is not bright and the low end is not plated. It is reflected in the coating that the coating is red or even Black, the color change in the hole is obvious.

3. The gold-plated current density of the pogo pin is too large

Due to the incorrect calculation of the total area of the plating tank parts, the value is larger than the actual surface area, the gold plating current is too large, or the amplitude of the gold plating is too small when the vibration plating is used, so that all or part of the gold plating in the tank has rough crystals, and the gold plating is visually impaired. layer redness.

Zhongzheng Technology has been deeply involved in the pogo pin connector industry for 10 years, providing thousands of high-precision pogo pin connector solutions for customers, and is a well-known enterprise in the industry. The company newly established an independent operating electroplating factory in 2019, to undertake the company's experience and concepts, to provide customers with high-quality products and services and welcome to negotiate and exchange.