The pogopin connector is a revolution in technology

A revolution in pogopin pogo pin connector technology, as analog circuits give way to digital circuits and electronic devices shift from wired connections to wireless connections, the design of the whole device is also developing from desktop to portable. As designs move toward portability, system durability becomes extremely important.

System design engineers have begun designing and constructing pre-tested modules, which are then stacked or blind-mated as a primary construction technique. This requires nanoscale interconnection devices. Manufacturers in the medical and even military/aerospace industries are pushing systems in this modular direction to meet the reductions in size, weight, and current required for complex signals. To meet these challenges, new connector designs must accommodate a combination of enhanced electrical performance and durability while reducing the size and weight of interconnecting systems.

Size and weight advantage

Improved machining, molding equipment, and materials have enabled further reductions in connector size in construction. Although the size and weight of both meet MIL-PRF-83513, the 21-position nano miniature connector weighs only 0.4g compared to the equivalent miniature D-shaped connector weighing 2.60g. In addition, 37-position miniature D-shaped connectors require 4 times more space than 37-position board mount or printed board connectors.

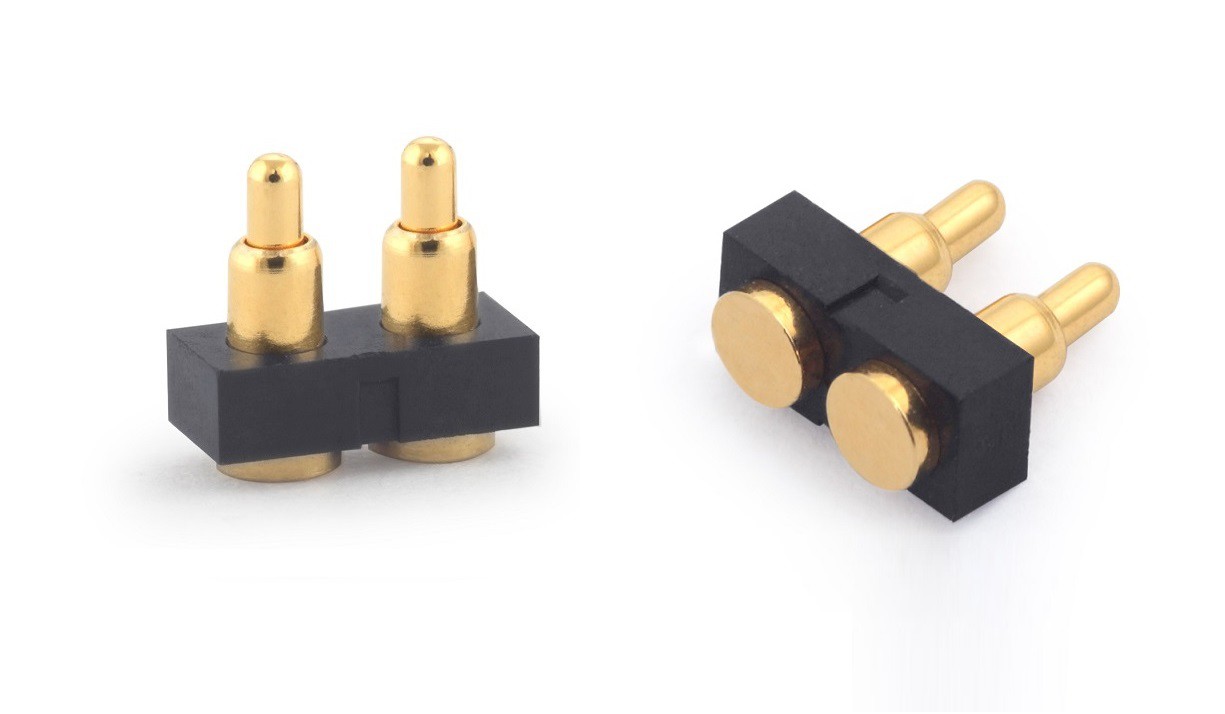

Design and material selection are key to successful size reduction. At the heart of the design are the elastic pins. A beryllium copper material with special tensile annealing properties is required to create high contact strength, low contact resistance, and maintain performance over thousands of mating cycles. Key specifications for beryllium copper thickness and length and shape ensure the long life and long-term performance of microminiature connector pins.

The insulating shell is mostly injection molded liquid crystal polymer, with some older designs using polyphenylene sulfide. When the 0.025" pitch results in only 10~11 mils of insulator between pins, this type of insulation still have high retention and high electrical dielectric strength. High-reliability PogoPin connector bodies can be used for plug-in and low vibrations made of insulating materials, but most high-vibration and high-shock applications require metal enclosures.

Durable reliability

Durability depends on good installation design. Force and acceleration are key factors in testing the strength of PogoPin connectors in harsh applications. Thanks to the reasonable mounting brackets, the Nano-PogoPin connector can pass over 10000Gs of vibration and shock, such as in fire and launch conditions.

Nano circular connector

Micro circular connectors (0.050" pitch) are large compared to nano circular PogoPin connectors. When fitted with pins and sockets with 0.025" pitch, in the same circular area, use 4 times more interconnect devices. Most of the new circuits require less than 1A of current because the digital processing allows smaller gauge wires to be used in the cable assembly to accommodate nano circular connectors. The overall weight and diameter of the interconnection system are thus greatly reduced. An additional benefit of nano-cables is increased flexibility, as smaller diameter cables are easier to route in severely constrained locations.

There are many styles of nano-circular connectors depending on the application, the metal shell type nano-circular connectors are the most durable, with excellent strain relief and handle mechanism. They feature 360 ferrules for shielded cables and are environmentally sealed to protect against impregnation. Typically, they are used to connect remote detectors, sensors, and instrumentation to the front panel of the device. The nano-circular connectors are molded or installed into the system engineer's own instrument. This approach saves most of the space and allows the device or detector to have its own complete motor and mechanical connectors.