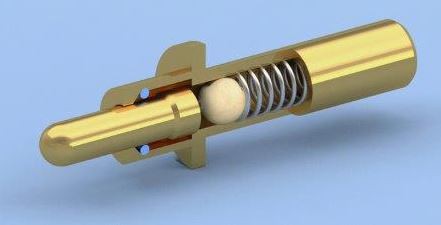

The composition of mold pogo Pin

POGO PIN mold thimble consists of three parts: needle plunger, Barrel, and elastic spring.

Needle Plunger: There are several plans for the needle tube of the mold Pogo pin.

1. Slope type: In order to ensure 100% contact between the needle tube and the needle tube during work, people cut the side where the needle tube and the elastic yellow touch into a slope. This kind of design concept can ensure a low and stable touch characteristic impedance, and can absolutely ensure the smooth on and off of the product.

2. Reversal hole type: In order to ensure 100% contact between the needle tube and the needle tube during work. Be able to consider the flexibility of customers. The length of the supporting facilities of this kind of design scheme can exceed the length of the syringe. Under the condition of restricted indoor space, the design scheme of the reversal hole can obtain stable elasticity and itinerary arrangement.

3. Three-side type: This kind of design scheme can not touch the needle tube and the needle tube in some cases, which will cause the current flow to be unable to go through the needle tube, and the wall thickness will follow the bullet yellow. The resistor is too large, the working voltage is greatly reduced, and the electronic equipment is turned off in an instant.

Barrel: The design syringe will be designed in accordance with the customer's structure of the interior space and the role of the product and the guarantee of its service life. Can show the design plan of general and opposite-sex friends to provide options.

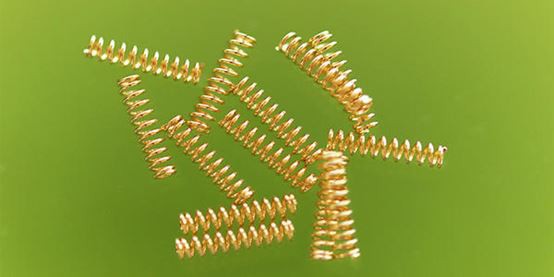

Sping: production process: high-precision computer machining, can very well ensure the precision of specifications, the precision can exceed, and the service life of the product can reach about 100,000 times.