Ball Pogo Pin, also known as a spring needle, Pogo Pin connector, or rolling ball spring-loaded Pin, primarily serves conductive or signal transmission functions.

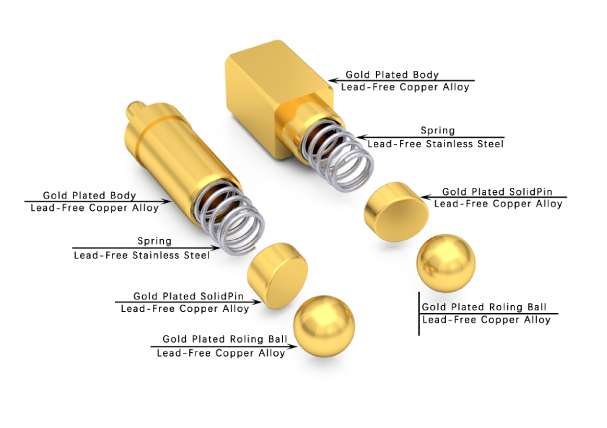

Pogo Pins adopts a steel ball + inclined structure design philosophy, primarily consisting of four core components: Rolling Ball, Solid Pin, Spring, and Body, and is assembled using precise molds and specialized equipment. The design of the inclined structure aims to ensure that Pogo Pins uses the lateral force generated by contact with the spring to maintain a stable contact force between the rolling ball and the Body, primarily through the gold-plated ball and Body, even during frequent insertion and removal.

Installation method for ball Pogo Pins:

SMT automatic soldering technology: The SMT automatic soldering machine automatically attaches ball Pogo Pins to printed solder paste PCB boards, precisely inserts solder pins into PCB board holes, and then melts and solidifies the solder paste through reflow welding to complete a fixed connection with the PCB pad. This process is fast, precise, and highly automated, significantly enhancing production efficiency and product quality.

2. Plugin Machine + Wave Soldering Technology: The automatic plug-in machine automatically attaches ball Pogo Pins and precisely inserts the solder feet into the printed solder paste PCB board. Then, the wave soldering process melts and fixes the paste, completing the fixed connection to the PCB pad. This process flow is fast, precise, and highly automated, significantly enhancing production efficiency and product quality. This method is particularly suitable for ultra-long solder joints that cannot be fixed in electronic components through SMD reflow welding.

Ball bearing Pogo Pin material and parts composition

Ball bearings Pogo Pin belong to a classification of Pogo Pin connectors, including upright contact and lateral contact types. This is an integrated spring connector designed based on a sloping structure, consisting of three core components: steel balls, SolidPin, Spring, and Body. Its unique feature is that its contact surface is a gold-plated ball that can rotate 360 degrees, significantly reducing wear on the contact surface. Due to its extremely low resistance, the connection is stable and reliable, making it characterized by long lifespan and durability.

Internal structure of ball Pogo Pin

The internal structure of the Pogo Pin uses a ball-and-slope design, ensuring stable and reliable contact between the ball and the syringe.

Vacuum blind hole electroplating technology

Vacuum blind hole electroplating technology is renowned for its outstanding performance, allowing for precise gold plating of extremely fine blind holes both inside and outside. This advanced electroplating process not only ensures the overall aesthetics of the metal surface but also offers excellent corrosion and wear resistance. Every detail, whether inside or outside the hole, displays a golden glow with no peeling or gold loss issues. The precision and stability of this technology ensure the durability and longevity of the electroplating layer, meeting various stringent application requirements.

Very low and stable contact resistance

By leveraging mature design, high-precision machining, and advanced vacuum blind hole electroplating technology, we achieved extremely low and stable contact resistance.

Standard sample