Electronic device composite plating

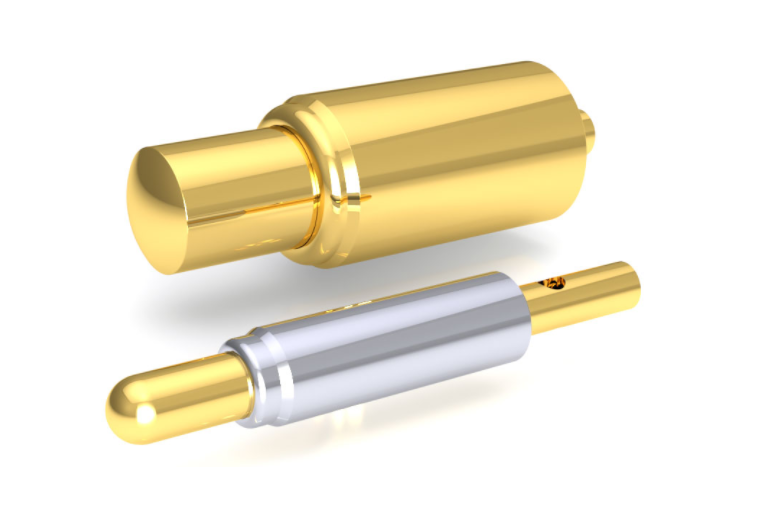

Composite plating development background: In the connector industry, pogo pin connection is a unique connector technology. This reliable technology is widely used in many electronic products, such as electronic cigarettes, mobile phones, chargers, antennas, POS machines, notebooks, headphones, magnetic interfaces, medical equipment, communication equipment, wearable devices, etc.

Pogo Pin Composite Plating

Especially sportswear products, which have wide application prospects and great demand, and often come into contact with the skin, will be exposed to a lot of sweat, and the fast charging current is large, which puts forward new requirements for the electrical performance and corrosion resistance of the products. At present, the traditional nickel plating gold process is increasingly unable to meet the development needs of customers, so a new electroplating process - a composite electroplating process that can meet the needs of customers has been developed.

Market Application of Composite Plating Seeds

3C Consumer Electronics New energy vehicles Industrial control equipment

Development of Composite Plating Seeds

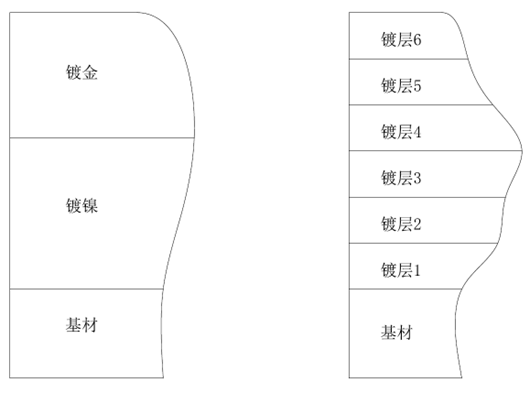

Traditional nickel-gold plating structure Composite seed coating structure

Advantages and disadvantages of traditional nickel-gold plating and composite plating

Representative composite plating_The outermost layer is rhodium-plated ruthenium/platinum-plated

Reasons for choosing rhodium-plated ruthenium and platinum: Rhodium-ruthenium and platinum metals have high hardness, good wear resistance, and superior electrical conductivity. They are commonly used precious metal gold plating metals for contact plug-in connector plating, and platinum-based metals themselves are extremely high. Electrochemical corrosion resistance, this type of plating is more and more used in consumer products that require electrolytic corrosion.

Development of Composite Plating Seeds

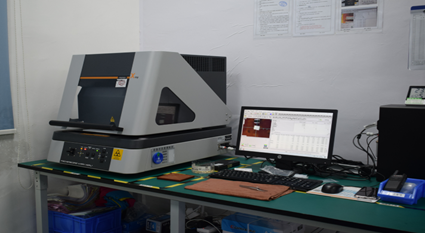

The analysis and control of the concentration of the potion require special analytical instruments and equipment.

Experimental Center

Special precision electroplating equipment

German film thickness meter that can measure multilayer film thickness

Nickel-free composite plating: The material and electroplating process do not involve any nickel-containing process;

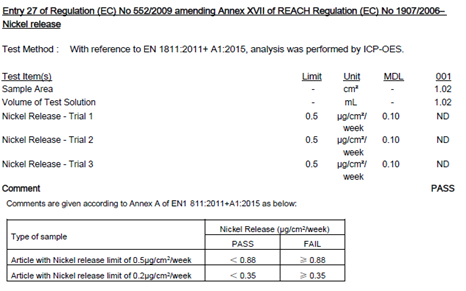

There are nickel composite plating species: that meet the nickel release requirements

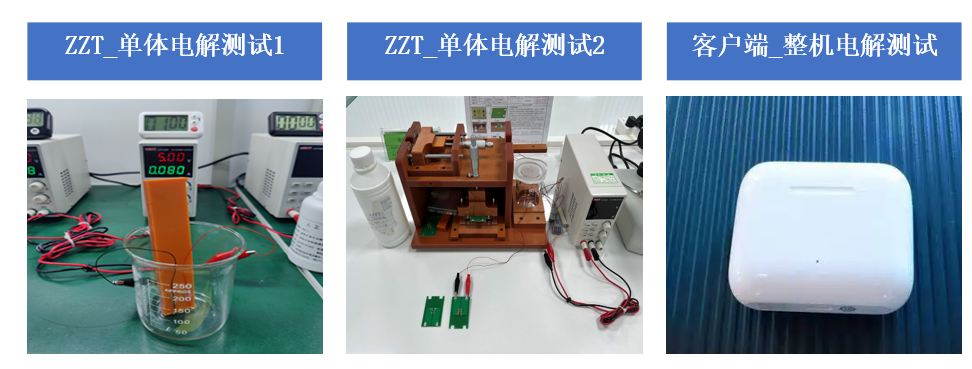

Composite plating electrolytic test method_3 kinds of test methods.