How to ensure the reliability of the internal connection of electronic products?

Electronic products such as smartphones, portable devices, and wearable devices are gradually becoming popular in China, and the frequency of use of narrow-pitch board-to-board spring thimble connectors has also increased. As consumers, the pursuit of a cool product experience is a never-ending demand, and lighter and thinner products have become more fashionable. However, for manufacturers of spring thimble connectors, how to ensure the reliability of the internal connections of electronic products has become a problem.

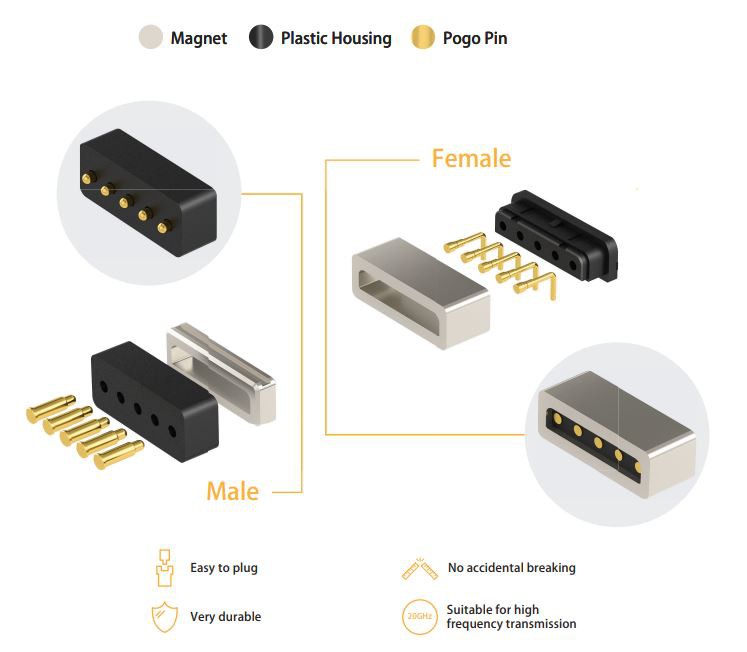

Generally speaking, the pogo pin connector is used to connect two PCBs or PCB and FPC to realize the mechanical and electrical connection. Its characteristic is that the male and female spring thimble pogo pin connectors are paired, so the spring thimble The plastic body and terminal of the pogo pin connector have strict matching requirements.

Flexible connection, easy to install, easy to disassemble.

The current board-to-board are all ultra-low heights to reduce the thickness of the fuselage. The current world's shortest board-to-board spring thimble connector combination height is 0.6mm. Minimizing the thickness of the product plays the role of connection, and this has led to more and more ultra-thin mobile phones on the market.

The contact structure has strong environmental resistance, not only flexible but also a "solid connection" with high contact reliability. In order to improve the combined force of the socket and plug, a simple lock is selected in the fixed metal part and the contact part. The buckle mechanism not only improves the combination force but also provides a more plug-in and pull-out feeling when locking. And some manufacturers provide a dual-contact structure to improve contact reliability. The pitch of the pins has also become narrower and narrower. The current mobile phone is mainly 0.4mm pitch. At present, Panasonic, JAE, and other manufacturers have developed 0.35mm pitch, which should be the narrowest board-to-board spring thimble connector in the industry so far. 0.35mm pitch is currently mainly used in Apple mobile phones and domestic high-end models. Its application will be the development direction in recent years. It has the smallest volume, highest precision, high performance, and other advantages, but it has requirements for patches and other supporting technologies. It is also higher. This is the most important problem that many spring thimble pogo pin connector manufacturers need to solve, otherwise, the yield rate will be very low.

In order to meet the requirements of the SMT process, the terminal soldering area of the entire product is strictly required to have a good coplanarity. The industry standard is usually 0.10mm (max), otherwise, it will cause poor soldering with the PCB and affect the use of the product. Influence.

The ultra-narrow board-to-board spring thimble pogo pin connector has new requirements for the electroplating process. For products with a height of 0.6mm and a single product less than 0.4 mm in height, how to ensure that the product's gold plating thickness and tin effect do not climb in? This is the most critical problem in the miniaturization of spring thimble connectors. The current industry’s common practice is to remove the gold-plated layer by laser to block the soldering path, so as to solve the problem of not climbing the tin. However, this technology has disadvantages, that is, peeling the gold. At the same time, the laser will damage the nickel plating layer, so that the copper is exposed to the air, causing corrosion and rust.