How to avoid the size error of the spring probe?

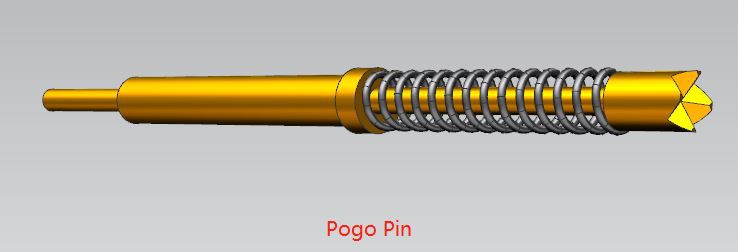

The needle tube and needle of the spring probe are made by turning and milling one by one copper rod; the traditional processing method is to use the cutting machine to process, the processed product has low precision and cost; it can be used in the spring probe Application areas where product accuracy is not high.

With the current popularity of smartphones and smart wearables, electronic products are becoming thinner and lighter; making the originally limited space smaller; in order to meet market demand, the volume of spring probe connectors is becoming smaller and smaller. The accuracy requirements of the needle are also getting higher and higher.

The accuracy of the spring probe products processed by different processing equipment is different, so how to avoid the size error of the spring probe?

First of all, the surface finish of the high-precision spring probe product is very high. The surface finish of the outer wall of the needle tube is not very affected, but the inner wall is affected. If the surface is very rough, the friction coefficient of the spring probe will be particularly large when it is elastically stretched. Stuttering may occur; the more important thing is that the friction coefficient is too large when working, which will cause the outer wall of the needle of the spring probe and the inner wall of the needle tube to wear very seriously, thus shortening the service life of the spring probe.

Secondly, the size error of the spring probe product is the product processed by the application of low-precision equipment, the size deviation will be relatively large, which will bring trouble to the later assembly and application, and the coordination may not be ideal.

We Located in Longgang District, Shenzhen, it has an independent factory building with an area of approximately 6,800 square meters. Integrating R&D, manufacturing, and sales, it is mainly engaged in R&D and production of various POGOPIN and POGOPIN connectors, shrapnel terminals, and CNC automatic lathe parts. It can also be produced and processed according to customer samples. There are more than 4000 product categories. For customers to choose, products (probe connector, pogo pin, pogo pin, spring connector, magnetic pogo pin, probe, charging pogo pin, magnetic pogo pin) are widely used in UAV smart robot smart wear products 5G Communication products, smart home products, education/entertainment electronic products, medical equipment products, automotive electronics, mobile phone consumer electronics and other electronic products.