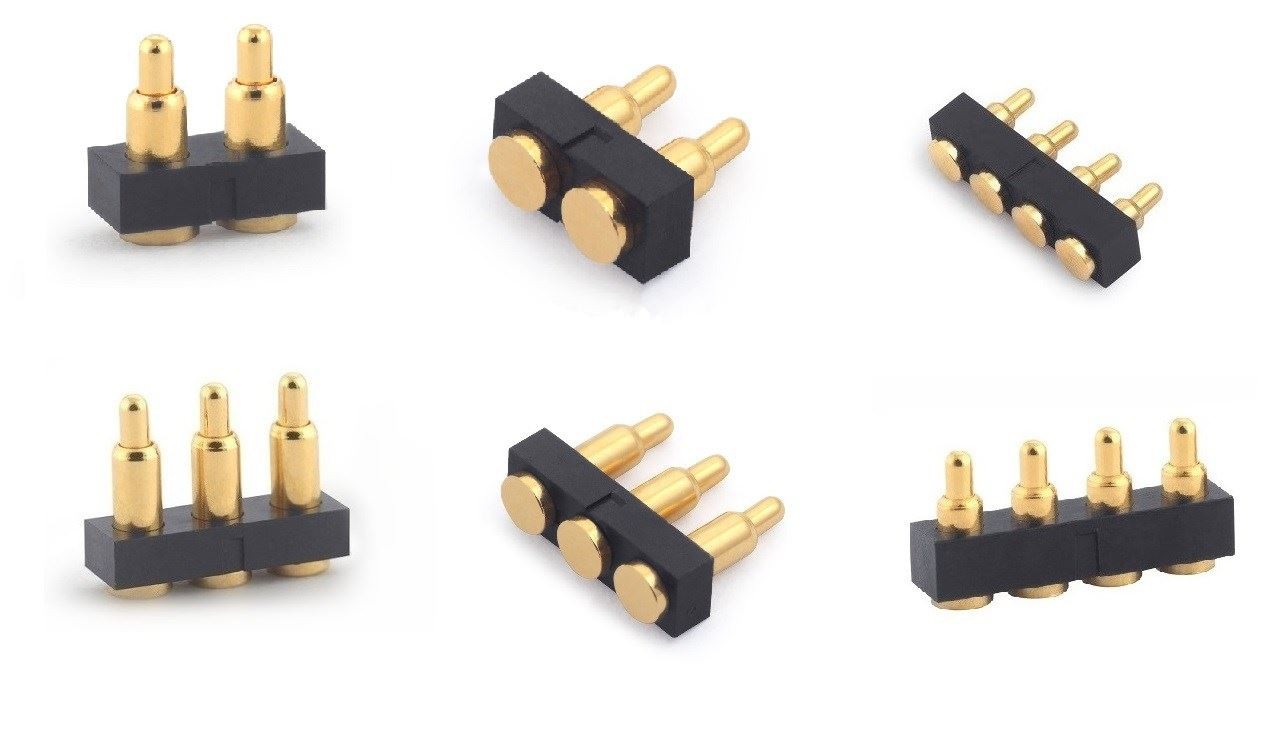

How does the coating thickness affect the durable of the pogo pin connector?

1. Pogo pin connector working stroke selection

The pogo pin connector is selected according to the product space and working stroke range. If the space is too small, the spring of the pogo pin connector will be greatly compressed, which will affect the service life. If the space is too large, it may cause poor contact, unstable impedance, and instantaneous image cut off.

2. Selection of plating materials

The electroplating material plays a role in enhancing conductivity, anti-oxidation, and anti-wear to the pogo pin connector. In fact, different materials perform different functions. For example, gold has excellent electrical conductivity. Therefore, for high-current connectors, products with high impedance requirements usually choose electroplated gold.

3. The influence of the thickness of the coating

During the operation of the pogo pin connector, there will be a certain amount of friction and wear due to contact, so the thickness of the coating has a great influence on the service life of the product. When used to a certain degree, the coating will be worn out, and the resistance will be too large and the impedance will be unstable. The coating of a 100,000-time pogo pin will definitely be thicker than that of a 10,000-time pogo pin, so when choosing a product, it must be plated according to the actual situation.

4. The impact of elasticity

The contact force of the spring connector comes from the internal spring. The spring force directly affects the resistance and stability of the spring. If the elastic force is too large, the friction coefficient will increase, which will affect the service life of the spring.