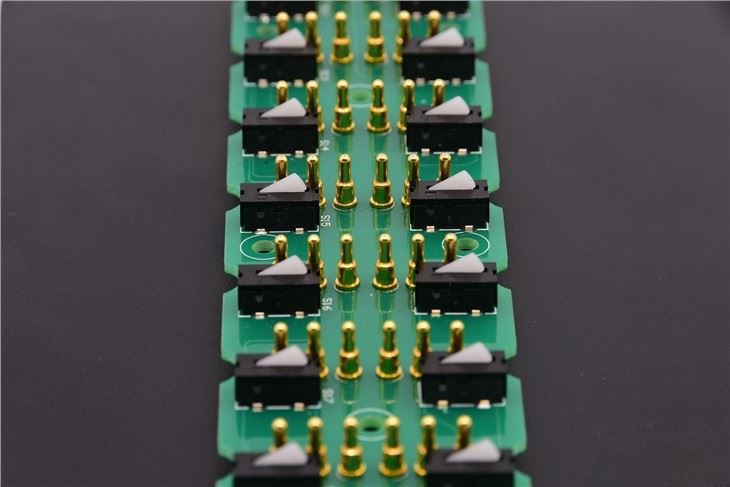

Spring-loaded Pogo Pins Pcb

Spring-loaded PCB pogo pins are essential components for accurate, reliable electrical connections in printed circuit boards. These pins are used in various industries where high-speed data transfer and high-frequency signal transmission are required.

Spring-loaded PCB pogo pins are designed with spring-loaded contacts that allow them to maintain contact with the mating surface even when subjected to vibration or shock. This feature ensures that the electrical connection remains secure and stable even during dynamic operation.

These types of pins are commonly used in applications where multiple PCBs need to be connected, such as in PCB manufacturing, test fixtures, and automated production equipment. They are also used in wireless communications equipment, mobile phones, and other portable electronic devices that demand high reliability and high-speed data transfer.

The benefits of using spring-loaded PCB pogo pins are numerous. Firstly, they provide a secure and stable electrical connection, ensuring that data transmission rates remain consistent without any signal loss. Additionally, their spring-loaded mechanism ensures that they can tolerate board size variations and slight misalignment between PCBs.

The construction of spring-loaded PCB pogo pins is also a benefit, as the pins are made of high-quality materials that provide them with high durability and longevity. They are also resistant to corrosion, rust, and oxidation, which extends their lifespan and ensures continued reliable operation.

In conclusion, spring-loaded PCB pogo pins provide a crucial component for a variety of electronic devices and equipment. Their reliability, durability, and consistent performance make them a preferred choice for many industrial applications requiring high-speed data transfer and high-frequency signal transmission.

POGO PIN is a very commonly used electronic connector. Its basic structure consists of a turning tube, a turning needle, and a compression spring. The mouth of the needle tube is crimped to keep the needle inside the needle tube, and the contact force is provided by the spring to establish an electrical connection between the needle and the docking parts. I believe many people do not know how POGO PIN is welded.

During the use of POGO PIN, the male and female ends are docked and the pogo pin compresses a certain stroke (compression amount 1.0mm, elastic force 70g±20g). It can be powered on, transmit signals, etc. to achieve various functions. Pogo Pin can be soldered on the PCB to make it fixed, or it can be fixed on the product structure, which requires professional design engineers to solve the problem.

The structure used for connecting the PCB board with zero working height and the POGOPIN connector, including the needle tube and the PCB board, a mounting hole is opened in the middle of the top of the PCB board, the needle tube is arranged inside the mounting hole, and the inside of the needle tube is provided with a connection structure, the connection structure It consists of a spring and a needle shaft. This kind of structure for connecting the PCB board with zero working height and the POGOPIN connector, through the elasticity of the spring, when the POGOPIN connector is connected with the PCB board, the pin shaft can be pushed into the interior, compressing the spring, so that the PCB board is The top is kept flat to achieve zero working height, and when the POGOPIN connector is separated from the PCB board, the needle shaft can protrude out of the inside of the needle tube under the action of the spring force, which improves the practicability.

How are pogopin pogo pins installed to Pcb?

First, surface mount

The pogo pin is usually installed stably, and the bottom of the needle tube is a flat bottom design, so we can use a vertical or horizontal package, which makes it easier to solder with the PCB. Also, some needles have locating pins on the end so there is no offset and it will work better.

Second, the straight solder tail installation method

Ordinary plug-in package for easy soldering. In addition, we often use tail-end plug-in packages, which also give pogo pin manufacturers more options in terms of space utilization.

Third, the floating installation

Mainly adopts double-head double-acting design, which is more suitable for connection without welding pressure, allowing engineers to have more space flexibility when making two-way board-to-board connections.

The above points are several installation methods of pogo pin spring thimble recommended for you today. There are many other installation methods for pogo pin spring thimble, but we still need to choose according to our actual situation.

Hot Tags: spring-loaded pogo pins pcb, China, suppliers, manufacturers, factory, customized, wholesale, buy, bulk, in stock, free sample

Send Inquiry