The main function of different series of connector contacts

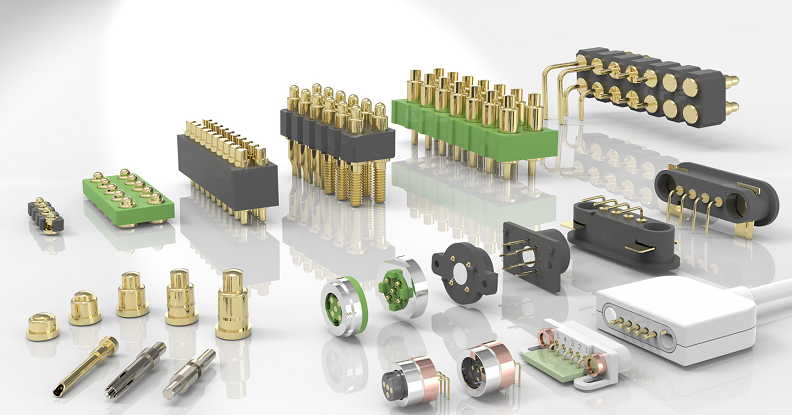

Usually, connector manufacturers produce multiple types of contacts for connectors when they produce connectors, because there is currently no single design connector contact suitable for all applications, so most connector manufacturers will produce a series of connector contacts to accomplish specific tasks. Below, Xinpengbo Electronic Technology mainly explains the main functions of different series of connector contacts.

The most important characteristic of any electrical contact is its resistance. For the sake of efficiency, designers should strive to ensure that the resistance of any circuit is kept as low as possible, after all, the lower the resistance, the less power is lost during transmission. Every component added to a circuit has the potential to increase resistance, and this is especially true of connectors.

The metal used to make the contacts, the plating, and the design of the contacts themselves can all help keep resistance low. However, it is important to remember that contact resistance is not static as external factors such as the environment and the number of times the contacts are connected and disconnected will affect the resistance of the contacts.

The physical life of connector contacts is measured in mating cycles. When two electrical contacts are mated, the metal bends as the contacts are displaced, and it's just a matter of watching carefully to see how the contacts move. This bending is important because it is a way designers use to ensure contacts stay together once mated, but bending itself creates stress within the metal. Over time, this can cause the contacts to loosen and the physical pressure between the two contacts will decrease.

Using the right materials can help achieve these effects. For applications that require high performance in harsh environments, phosphor bronze can be an option instead of brass as the base material. The superior elasticity and properties of phosphor bronzes mean they can withstand more cycles while still providing good electrical contact. The increase in connector performance makes the extra material cost worth paying.

One of the biggest factors affecting connectors is temperature. Despite the best efforts of the designer, each contact will have some resistance, and some energy will be lost as heat as current flows through the contact. For signal connectors, this doesn't matter, but for connectors that are intended to be live, this can quickly become a source of new problems, even power contacts rated to carry high currents can get hot.

If the connector is used in a high-temperature environment (for example, under the hood of a car), the additional temperature rise can cause damage. The good thing is that temperature rises are predictable and connector manufacturers can publish different graphs to help users understand the effect of temperature on current flow. These graphs can show how a rise in current will affect temperature, or inform the user of the recommended maximum current for a specific condition, and with this level of technical detail, customers can confidently specify the connectors they need.

The design of connectors and contacts can be said to be a long-term topic, and it is necessary to study the various properties of contacts. While contact is at the heart of every connector, there are many other factors that affect signal integrity and environmental performance.