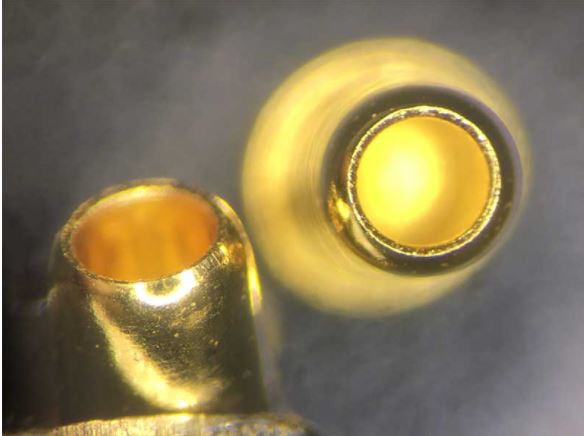

The difference between gold plating and palladium plating

There are many electroplating processes and materials. Gold plating is our most common processing technology and material, but palladium plating, rhodium plating, and ruthenium plating are better than gold plating. This is palladium plating.

Gold plating uses real gold, and even if only a thin layer is plated, it already accounts for nearly 10% of the cost of the entire circuit board. Gold plating uses gold as a coating, one is to facilitate welding, and the other is to prevent corrosion; even the gold fingers of memory sticks that have been used for several years are still as shiny as ever. Advantages: strong conductivity, good oxidation resistance, long life; dense coating, relatively wear-resistant, generally used in welding and plugging occasions. Disadvantages: high cost, poor welding strength.

Gold / Immersion Gold Nickel Immersion Gold (ENIG), also known as nickel gold, immersion nickel gold, referred to as gold, and immersion gold. Immersion gold is a thick layer of nickel-gold alloy with good electrical properties wrapped on the copper surface by chemical methods and can protect the PCB for a long time. The deposition thickness of the inner layer of nickel is generally 120~240μin (about 3~6μm), and the deposition thickness of the outer layer of gold is generally 2~4μinch (0.05~0.1μm). Immersion gold enables the PCB to achieve good electrical conductivity during long-term use, and also has environmental tolerance than other surface treatment processes do not have. Advantages: 1. The surface of the PCB treated with immersion gold is very flat, and the coplanarity is very good, which is suitable for the contact surface of the button.

Immersion gold has excellent solderability, and gold will quickly melt into the molten solder to form a metal compound. Disadvantages: The process flow is complex, and to achieve good results, it is necessary to strictly control the process parameters. The most troublesome thing is that the surface of the PCB treated with immersion gold is easy to produce the black disk effect, which affects the reliability.

Compared with nickel-palladium-gold, nickel-palladium-gold (ENEPIG) has an extra layer of palladium between nickel and gold. In the deposition reaction of replacing gold, the electroless palladium layer will protect the nickel layer and prevent Excessive corrosion by exchanging gold; palladium is fully prepared for immersion gold while preventing corrosion caused by the replacement reaction. The deposition thickness of a nickel is generally 120~240μin (about 3~6μm), the thickness of palladium is 4~20μin (about 0.1~0.5μm); the deposition thickness of gold is generally 1~4μin (0.02~0.1μm).

Advantages: Wide range of applications, at the same time, nickel palladium gold is relatively immersion gold, which can effectively prevent connection reliability problems caused by black disk defects. Disadvantages: Although nickel palladium has many advantages, palladium is expensive and is a shortage of resources. At the same time, like immersion gold, its process control requirements are strict.