Solutions of defective Pogo pin Connector

Defective Pogo pin product from Lathe mahine when manufactring.

Turning head

Description:

P21 Lathe machine ZK200063-W09-PP, the turning material head is not removed, and it is found by random inspection.

Solution:

The first product on the lathe must be taken and then discarded. This take-up and take-out head action is 100% executed for each machine.

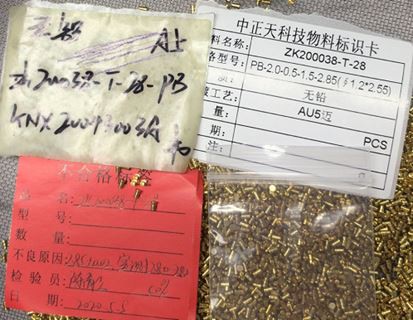

2. Material sampling -Bad riveting size

Description:

A5 machine ZK200038-T-28, riveting size 2.85±0.02 random inspection 2.80-2.82, defective rate 50%, this product is scrapped.

Sulotion:

A5 machine tool adjustment problem affected, has been adjusted on-site.

3. Turning Spring tube twist

Description:

A15 machine ZK2000345-side, the needle tube is twisted, the defect rate is 10%

Sulotion:

The machine is defective, the output product has been re-selected, and the defective product is scrapped.

4. Needle length

Description:

The P20 machine produces ZK200065-L08-PP, the needle has length, step 1.3, measured 1.2-1.22, and the defect rate is 3%.

Sulotion:

The machine is defective, the output product has been re-selected, and the defective product is scrapped

5. Lathe Defects-Lathe Processing Discovery

Chamfer too big

Description:

4.22-A15 machine ZK200045-T05-2, the drawing requires chamfering 0.05, measured 0.17, defective 10% (defects are found in both shifts), the appearance is obviously unacceptable visually.

Sulotion:

The machine has been tuned, and the output is scrapped

6.Bulge on the bottom of the barrel

Description:

A13 machine ZK200040, the bottom of the needle tube is bulging, which is too deep by the drill bit, the bottom becomes thin and bulging, which is unacceptable.

Solution:

The machine has been tuned, and the output is scrapped.

7. Assembly inspection

Description:

ZK200042-T-32, the needle diameter is large, the turning is not in place, and it jams after assembly.

Solution:

The machine is defective, the output product has been re-selected, and the defective product is scrapped.

8. Barrel surface step

Description:

ZK200050-D15-T35, the needle tube shows that there is a turning step that does not match the drawing, which is obviously unacceptable visually.

Solution:

This is the old material of 2019.11, the output product has been re-selected, and the defective product is scrapped.

Defective Pogo Pin when plating

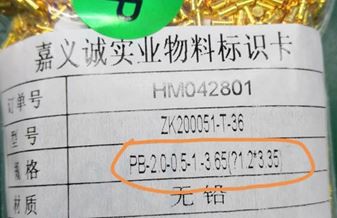

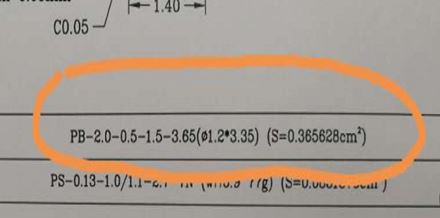

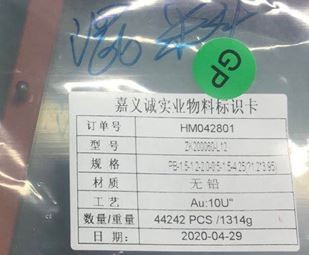

1.Electroplating label specification error

Description:

The label specifications of the gold-plated product ZK200051-T-36 have few numbers, which are not in line with the drawing.

Solution:

This is the old material of 2019.11, the output product has been re-selected, and the defective product is scrapped.

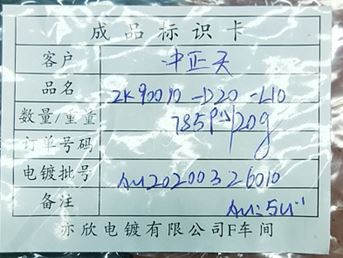

2. Barrel Mix

Description:

4/28 delivery note ZK200060-L12, a total of 10 packs, and the actual delivery material contains a pack of ZK200060-W08-L10,

This is the wrong material sent by the warehouse (ZK200060-W08-L10 does not need to send electroplating on the same day).

Solution:

1. The warehouse is only allowed to place the materials that need to be plated on the day when the materials are distributed, and all other non-plated materials are isolated from the delivery site.

2. When the electroplating factory receives the materials, it also helps to confirm whether the materials are consistent with the delivered ones.

3. The surface of the car part is whitish

Description:

The gold-plated surface of the car parts is whitish due to the lack of bright nickel plating.

Solution:

Gold plating can only be done after the appearance of nickel plating is confirmed OK.

4.Lathe parts blistering after passing the furnace

Description:

Poor electroplating process control

Solution:

Quality control and 100% inspection.