Precision Electronic Connectors

Precision electronic connectors are often used when connecting circuits. In order to ensure circuit safety during use, electrical parameters are the first place users need to consider when selecting electronic components. Next, I'll show you how to use it properly.

1. Logo

The marking on the relay module product can remind the user how to install and use it correctly. Therefore, the manufacturer will mark the rated voltage, current, power characteristics, and other parameters of the precision electronic connector in an obvious position. Do not easily tear off these expressions when using them.

2. Rated value

It can ensure that all electrical data meet the rated requirements during connection and use. Users need to use it within the rated value range and cannot exceed the rated use value.

3. Size

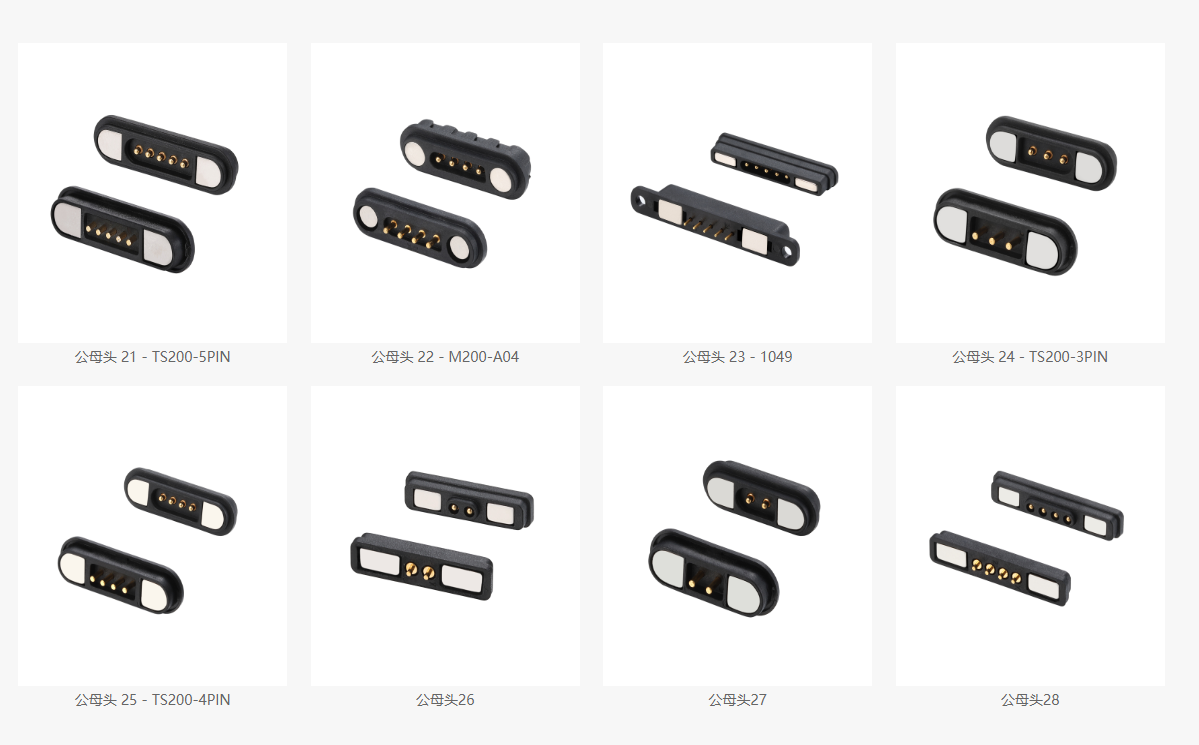

At present, there are various specifications of circular connector precision electronic electrolyzers, and some surfaces look similar in size, but they have poor contact or even cannot match when inserted. Therefore, the selected size must meet the requirements of the insertion.

4. High temperature

When the precision electronic connector is in a high-temperature state, the structure and characteristics of the insulating material will change, thus affecting the safety of use. Therefore, when used in a high-temperature environment, it is necessary to select insulating materials with flame retardant properties.

5. Insert components

The socket assembly should have a certain elasticity in order to obtain a good insertion force when inserted. The socket should have good wear resistance and corrosion resistance, otherwise, there will be potential safety hazards during use, and the mating surface will be tight when mating.

When using precision electronic connectors, you must pay attention to the correct use. After all, improper use may cause accidents such as short circuits and leakage.