A basic introduction to POGO PIN

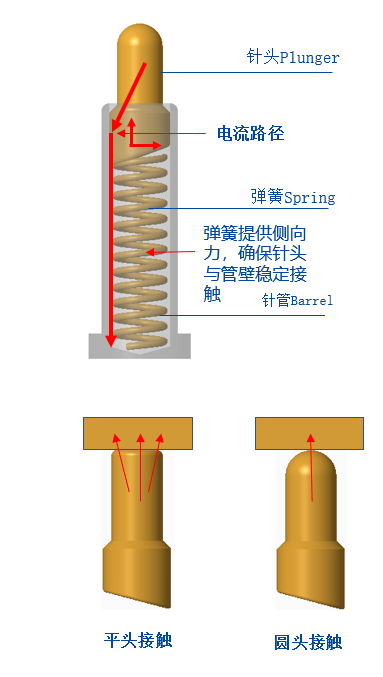

Why does POGO PIN have a beveled structure: The bottom of the Plunger of the Pogo Pin is usually a beveled structure. The function of the beveled structure is to ensure that the Pogo Pin keeps the needle (Plunger) in contact with the inner wall of the needle (Tube) when it is working so that the current mainly passes through. Gold-plated needle (Plunger) and needle (Tube) to ensure the stability and low impedance of Pogo Pin.

Why does POGO PIN use a round head structure? Because Pogo Pin is usually relatively small, the elasticity required is not so strong. If it is used on a power bank or lighting, the elasticity is four to five hundred grams or even one or two kilograms. Naturally, it is better to make it flat. , The contact area of the flat head is significant, and its force is enough to break the oxide layer of the contact surface and make it fully contact. Most of the round heads are used on TWS Bluetooth headsets and smart bracelet watches. The maximum elastic force does not exceed 150 grams (the elastic force of the thimble of the charging box is between 20-35gf), and the contact between the surface and the surface will be dispersed, and the copper column at the headphone end will not be broken. The oxide layer is insufficient, resulting in poor contact and poor contact. At this time, if a round head structure is used to make point-to-surface contact, the elastic force gathers on one point, and the contact will naturally be much more sufficient.

Performance parameter/performance parameter

key performance parameters

A. Working voltage: Less than 12 Volts DC

B. Rated current: 1.0 Amperes /Pin

C. Working temperature: -40°C to 85°C.

D. Storage temperature: 25℃+/-3℃.

E. Working environment humidity: 10%R.H. to 90% R.H.

F. Durability (life): 10,000 cycles.

G. Contact resistance: 200 mOhm Max. @working stroke

(During working stroke: 200mOhm/Max)

Pogo Pin Manufacturing process

Pogo pin Assembly method/product assembly method

Pin (Plunger): Brass gold-plated (C3604), the thickness of the electroplating layer varies according to different applications. Generally, nickel-plated 1.25~2.5um (converted to 50~100µ ”), and then gold-plated 0.075 ~0.75um (converted to 3~30µ ”), or composite plating process.

Needle tube (Barrel): Brass gold-plated (C3604), the thickness of the electroplating layer varies with different occasions. In general, nickel-plated 1.25~2.5um (converted to 50~100µ ”), and then gold-plated 0.075 ~0.75um (converted to 3~30µ ”), or composite plating process.

Spring: SUS 304 or SWP (piano wire)

Housing: PA46, PA9T, of which PA4T and LCP can be used as halogen-free material

Cover (CAP): PA46, PA9T, of which PA4T and LCP can be made of halogen-free materials

What parameters need to be confirmed when using Pogo pin in front-end design?

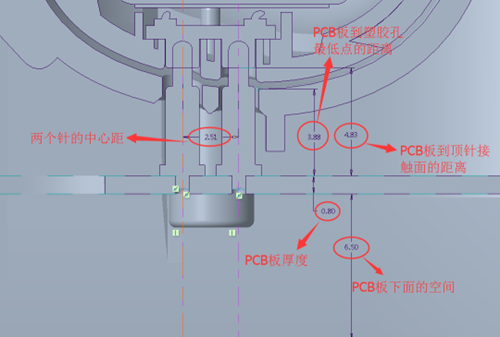

① Confirm the distance from the PCB board to the contact surface of the copper column on the earphone end (that is, the working height of the POGO PIN).

② Confirm the distance from the PCB board to the plastic surface of the charging box (that is, the maximum height of the POGO PIN needle, the needle must not exceed this height).

③ Confirm the distance between the center of the PIN needle and the center of the circle

(Confirm the size of the hat when taping later, to prevent interference during SMT patching).

④ Confirm the size of the PCB board and the space under the board

(Optimized and improved for POGO PIN).

PS: The diameter of the PCB board is recommended to be 1.6mm, and the thimble is recommended to be made into a through-board structure so that the effect is better and has the following advantages: ① The patch is firmer; ② The needle tube space is increased, the needle is pre-pressed more, and the contact is more sufficient.

Why should the bottom of the needle be beveled: If it is made flat, the current will be conducted by the spring, which has high requirements on the spring, and the spring is so thin that it is easy to burn out.