Factors considered when spring pogo pin partial gold plating

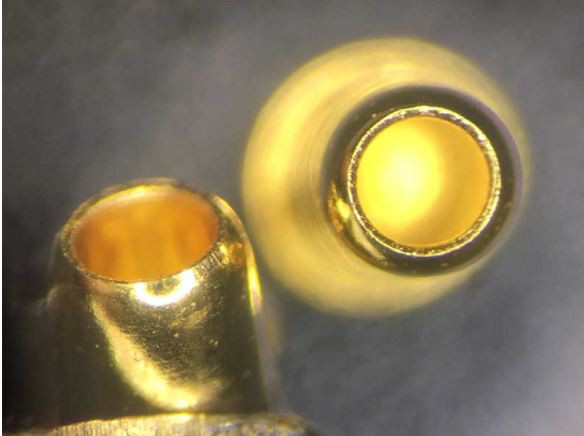

Pogopin's entire product is not only important for needles, needle tubes, and springs, but also for its electroplating. Electroplating can directly affect the quality of a finished product and can determine whether the quality of a product is passed or will be scrapped. If the spring is not plated with gold, it will not be able to carry a large current, and pogo pins will not have such stable signal and conductivity without gold plating.

However, the cost of gold plating is relatively high, so some customers will choose different plating methods, and in order to meet the needs of customers, they will choose partial gold plating. Using this method can reduce costs, but there are other considerations.

Pogo pin spring thimble should consider the following points when selecting partial gold plating:

1. Productivity should be considered, and a device that can withstand current density should be selected

2. the thickness uniformity of the pogo pin spring thimble plating layer is better

3. pogo pin spring thimble plating position accuracy should be high

4. It is necessary to select a device that can flexibly correspond to various substrate plating methods

5. When the substrate is changed or the method is changed, it can be adapted only by simple adjustment